Flushing Ring · Drip Ring · Bleed Ring

Flush Ring

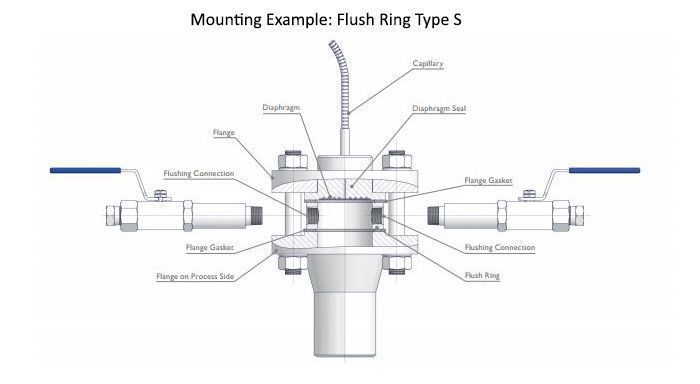

Flushing Rings are designed to be sandwitched between the process flange and the disphragm seal in order to avoid the formation of deposits or blockages by the process conditions and the geometry of the connection which could make the medium into deposites or blockages. Flush Ring Manufacturer Mumbadevi Steel India (MSI) offers grades such as Inconel Flush Ring, Incoloy Flush Ring, Monel Flush Ring, Hastelloy Flush Ring, Stainless Steel Flush Ring, Titanium Flush Ring, Duplex 2205 Flush Ring, Super Duplex Flush Ring, Copper Nickel Flush Ring, Alloy 20 Flush Ring, Nickel 200 Flush Ring, 254 SMO Flush Ring, Brass Flush Ring, AISI 4130 Flush Ring.

Drip Ring

Drip Rings are used in applications where Plugging may occur or where in-situ calibration is required without removing the instrument from the process. Drip Rings can be supplied with either 1 or 2 ports. Drip Rings are fitted between Flange seals and flanged process connections. Drip Ring Manufacturer Mumbadevi Steel India (MSI) offers grades such as Inconel Drip Ring, Incoloy Drip Ring, Monel Drip Ring, Hastelloy Drip Ring, Stainless Steel Drip Ring, Titanium Drip Ring, Duplex 2205 Drip Ring, Super Duplex Drip Ring, Copper Nickel Drip Ring, Alloy 20 Drip Ring, Nickel 200 Drip Ring, 254 SMO Drip Ring, Brass Drip Ring, AISI 4130 Drip Ring.

Bleed Ring

Bleed Rings is similar to a Spacer Ring, but it doesn’t have a handle. Bleed Rings have one or more radial pipe connections and are fitted inside the circular bolts between the standard flanges that connect valves or instruments. Used to relieve pressure or drain fluids. Bleed Ring Manufacturer Mumbadevi Steel India (MSI) offers grades such as Inconel Bleed Ring, Incoloy Bleed Ring, Monel Bleed Ring, Hastelloy Bleed Ring, Stainless Steel Bleed Ring, Titanium Bleed Ring, Duplex 2205 Bleed Ring, Super Duplex Bleed Ring, Copper Nickel Bleed Ring, Alloy 20 Bleed Ring, Nickel 200 Bleed Ring, 254 SMO Bleed Ring, Brass Bleed Ring, AISI 4130 Bleed Ring.

Flush Ring · Drip Ring · Bleed Ring · Diaphragm Seal Accessories

Flush Rings also known as Drip Ring or Bleed Ring or Diaphragm Seal Accessories supplied by Mumbadevi Steel India (MSI) , have the same diameter as the flanges, bringing the valves clear of the flanges and eliminating the need for flushing port extension adapters. Drip Rings are held in place by through-bolts or captive studs, making them easy to install. The captive stud versions have the added advantage that the drip ring stays in place if either the process valve side or the diaphragm side requires removal. Bleed Rings also have the benefit of allowing for size reduction. Mumbadevi Steel India (MSI) produces a variety of tapered bore Flush Ring or Drip Ring or Bleed Ring, typically with a 2” process-side flange and a 3” diaphragm-side flange to allow use of larger diaphragms for improved measurement accuracy without having to employ unnecessarily large and heavy valves. Material collected in front of diaphragm can be flushed out through the flushing ports, or the pressure volume can be vented. Various nominal sizes and forms allow adaption to the respective process flange. Flushing Rings also reffered to as drip rings, are used between an isolation valve and the diaphragm seal of a pressure transmitter. Flush rings are used for diaphragm seals in order to prevent clogging of the instrument connection. Flushing Ring also known as calibration ring, as it is used to apply known pressure and calibrate transmitter against known pressure. Flushing rings are simply mounted between the flanged process connection and the diaphragm seal. The two flushing ports allow washing out of particles accumulated in front of the membrane and the pressure space can be vented or drained according to requirement. Side ports on the rings allow media to be injected/ejected so that the diaphragm can be flushed free of deposits that affect transmitter measurement accuracy.

Mumbadevi Steel India (MSI) is Certified and CRISIL MSE 4 Rated company from India. We export best quality Diaphragm Seal Accessories in Nickel Alloy, Stainless Steel, Inconel, Hastelloy etc grades finished according to standards and specifications. Contact for best price on Flushing Rings or Drip Rings or Bleed Rings. Mumbadevi Steel India (MSI) can supply the Flush Ring or Drip Ring or Bleed Ring ready-fitted with ball valves for flushing or needle valves. The flushing flange or ring is used for flushing solution combined with diaphragm seals. This type of flushing flange or ring is clamped between process nozzle and diaphragm seal. Flush Ring or Drip Ring or Bleed Ring comes in many different materials such as Inconel Flushing Ring, Incoloy Flushing Ring, Monel Flushing Ring, Hastelloy Flushing Ring, SS Flushing Ring, Titanium Flushing Ring, Duplex 2205 Flushing Ring, Super Duplex Flushing Ring, Copper Nickel Flushing Ring, Alloy 20 Flushing Ring, Alloy 200 Flushing Ring, 254 SMO Flushing Ring, Brass Flushing Ring, AISI 4130 Flushing Ring, Duplex 2205 Drip Ring, Super Duplex Drip Ring, Copper Nickel Drip Ring, Alloy 20 Drip Ring, Alloy 200 Drip Ring, Titanium Drip Ring, 254 SMO Drip Ring, Brass Drip Ring, AISI 4130 Drip Ring, Duplex 2205 Bleed Ring, Super Duplex Bleed Ring, Copper Nickel Bleed Ring, Alloy 20 Bleed Ring, Inconel Drip Ring, Incoloy Drip Ring, Monel Drip Ring, Hastelloy Drip Ring, SS Drip Ring, Inconel Bleed Ring, Incoloy Bleed Ring, Monel Bleed Ring, Hastelloy Bleed Ring, Alloy 200 Bleed Ring, Titanium Bleed Ring, 254 SMO Bleed Ring, Brass Bleed Ring, AISI 4130 Bleed Ring, SS Bleed Ring.

Technical specifications:

- Process Connection: DN 50, 80, 100, 125 or NSP 2", 3", 4", 5", PN 16-100 or Class 150-600.

- Sealing Faces: Suitable for Raised Face Flange.

- Flushing Connection: ½" NPT female (without plug screws).

- Pressure Rating: 150lbs up to 2500lbs, others on request.

- Flange Sizes: 1/2″ (DN15) up to 4” (DN100), Special version, to be specified.

- Flushing Port Size: 1/2-14 NPT (F), 1/4-18 NPT (F).

- Installation: The flushing ring is clamped between process flange and diaphragm seal using standard sealing elements (seals to be ordered separately).

Additional specifications:

- Materials: Inconel, Incoloy, Monel, Hastelloy, Stainless Steel, Titanium, Duplex 2205, Super Duplex, Copper Nickel, Alloy 20, Nickel 200, 254 SMO, Brass, AISI 4130., With Acceptance Certificate per EN 10 204 - 3.1 B.

- Sealing Faces: Per EN 1092-1 form B2 or per ASME B 16.5 RFSF, 500 AA, 125 AA, Per EN 1092-1 form C (tongue), form D (groove), Per ASME B 16.5 RJF (Ring joint face), Other forms of sealing faces on request.

- Flushing connection: G ½", G º", º" NPT female, ½" NPT, G ½ B, G º B, º" NPT male, With plug screws.

Available Grades

- Inconel 600 Flushing Ring

- Inconel 601 Flushing Ring

- Inconel 625 Flushing Ring

- Inconel 718 Flushing Ring

- Incoloy 800 Flushing Ring

- Incoloy 800H Flushing Ring

- Incoloy 800HT Flushing Ring

- Incoloy 825 Flushing Ring

- Monel 400 Flushing Ring

- Monel K500 Flushing Ring

- Hastelloy B2 Flushing Ring

- Hastelloy C22 Flushing Ring

- Hastelloy C276 Flushing Ring

- Stainless Steel 304 Flushing Ring

- Stainless Steel 304L Flushing Ring

- Stainless Steel 304H Flushing Ring

- Stainless Steel 316L Flushing Ring

- Stainless Steel 316H Flushing Ring

- Stainless Steel 316Ti Flushing Ring

- Stainless Steel 321 Flushing Ring

- Stainless Steel 321H Flushing Ring

- Stainless Steel 347 Flushing Ring

- Stainless Steel 347H Flushing Ring

- Stainless Steel 904L Flushing Ring

- Stainless Steel 309 Flushing Ring

- Stainless Steel 310 Flushing Ring

- Stainless Steel 317L Flushing Ring

- Stainless Steel 330 Flushing Ring

- Titanium Grade 1 Flushing Ring

- Titanium Grade 2 Flushing Ring

- Duplex 2205 Flushing Ring

- Super Duplex 2507 Flushing Ring

- Super Duplex 4501 Flushing Ring

- Copper Nickel 90/10 Flushing Ring

- Copper Nickel 70/30 Flushing Ring

- Alloy 20 Flushing Ring

- Alloy 200 Flushing Ring

- Alloy 201 Flushing Ring

- 254 SMO Flushing Ring

- Brass Flushing Ring

- AISI 4130 Flushing Ring

- Duplex 2205 Drip Ring

- Super Duplex 2507 Drip Ring

- Super Duplex 4501 Drip Ring

- Copper Nickel 90/10 Drip Ring

- Copper Nickel 70/30 Drip Ring

- Alloy 20 Drip Ring

- Alloy 200 Drip Ring

- Alloy 201 Drip Ring

- Titanium Grade 1 Drip Ring

- Titanium Grade 2 Drip Ring

- 254 SMO Drip Ring

- Brass Drip Ring

- AISI 4130 Drip Ring

- Duplex 2205 Bleed Ring

- Super Duplex 2507 Bleed Ring

- Super Duplex 4501 Bleed Ring

- Copper Nickel 90/10 Bleed Ring

- Copper Nickel 70/30 Bleed Ring

- Alloy 20 Bleed Ring

- Inconel 600 Drip Ring

- Inconel 601 Drip Ring

- Inconel 625 Drip Ring

- Inconel 718 Drip Ring

- Incoloy 800 Drip Ring

- Incoloy 800H Drip Ring

- Incoloy 800HT Drip Ring

- Incoloy 825 Drip Ring

- Monel 400 Drip Ring

- Monel K500 Drip Ring

- Hastelloy B2 Drip Ring

- Hastelloy C22 Drip Ring

- Hastelloy C276 Drip Ring

- Stainless Steel 304 Drip Ring

- Stainless Steel 304L Drip Ring

- Stainless Steel 304H Drip Ring

- Stainless Steel 316L Drip Ring

- Stainless Steel 316H Drip Ring

- Stainless Steel 316Ti Drip Ring

- Stainless Steel 321 Drip Ring

- Stainless Steel 321H Drip Ring

- Stainless Steel 347 Drip Ring

- Stainless Steel 347H Drip Ring

- Stainless Steel 904L Drip Ring

- Stainless Steel 309 Drip Ring

- Stainless Steel 310 Drip Ring

- Stainless Steel 317L Drip Ring

- Stainless Steel 330 Drip Ring

- Inconel 600 Bleed Ring

- Inconel 601 Bleed Ring

- Inconel 625 Bleed Ring

- Inconel 718 Bleed Ring

- Incoloy 800 Bleed Ring

- Incoloy 800H Bleed Ring

- Incoloy 800HT Bleed Ring

- Incoloy 825 Bleed Ring

- Monel 400 Bleed Ring

- Monel K500 Bleed Ring

- Hastelloy B2 Bleed Ring

- Hastelloy C22 Bleed Ring

- Hastelloy C276 Bleed Ring

- Alloy 200 Bleed Ring

- Alloy 201 Bleed Ring

- Titanium Grade 1 Bleed Ring

- Titanium Grade 2 Bleed Ring

- 254 SMO Bleed Ring

- Brass Bleed Ring

- AISI 4130 Bleed Ring

- Stainless Steel 304 Bleed Ring

- Stainless Steel 304L Bleed Ring

- Stainless Steel 304H Bleed Ring

- Stainless Steel 316L Bleed Ring

- Stainless Steel 316H Bleed Ring

- Stainless Steel 316Ti Bleed Ring

- Stainless Steel 321 Bleed Ring

- Stainless Steel 321H Bleed Ring

- Stainless Steel 347 Bleed Ring

- Stainless Steel 347H Bleed Ring

- Stainless Steel 904L Bleed Ring

- Stainless Steel 309 Bleed Ring

Flushing Ring Special Features:-

- - Flush Ring has Captive stud option.

- - Drip Ring is easy to fit with through holes for studding.

- - Bleed Rings are available in a range of corrosion resistant alloys.

- - Integral welded valves, no threads or PTFE required for Flushing Ring.

- - Pressure chamber can be vented by means of Drip Rings.

- - Weld extensions gives added clearance for Bleed Rings, away from chemical seal.

- - Material collecting can be flushed out through the lateral flushing boreholes.

- - Flush rings for sour gas service are available in accordance with NACE MR0175/ MR0103 and ISO 15156 by default.

Drip Ring Applications:-

- - Chemical injection.

- - Process to instrument interface.

- - With Double Flushing Ports.

- - Suitable with Flanged, Pancake or Inline Diaphragm Seals.

- - Mounted between the process flange and the diaphragm seal.

- - Used for diaphragm seals in order to prevent clogging of the instrument connection.

- - Pressure chamber can be vented or drained or filled with a cleaning liquid and subsequently flushed.

- - Pipe plugs and various valves.

Difference Between Drip Ring and Bleed Ring

There is not much difference between a Bleed Ring and a Drip Ring. Majority of companies call them bleed rings because they allow bleeding pressure or mount pressure gauges or other sensors into a piping system. Drip Ring is a ring section with one or more radial pipe connections designed to fit between standard flanges within the bolt circle, using conventional gasket material. Bleed ring normally comes with a 1/2 inch socket weld or 3/4 inch tapped for connecting with valves and instruments. The face of the Drip Ring can also be made to matched with any flange type, and has different sizes based on the ASME flange rating of the process piping. Bleed Rings can provide a beneficial way of draining piping, taking samples, attaching instruments or even bleeding of a valve. Drip Rings can also be used with a valve and/or blind flange, this allows you to reduce and dispose of the pressure for your valve before you remove the flange. This is usually done with a replacement for a leaky valve. The bleed ring can come in any material or size, and is designed for connecting valves and instruments. The face of the Drip Ring can be manufactured to match with any flange type. The standard sizes for a Bleed Ring or Drip Ring are NPS 1 to NPS 24 and ASME Pressure Classes 150 through 1500.