Piping Color Codes

Color coding of pipelines and piping materials are standard industry practices. Color marking will make identification easier for raw material and fluid that being transport by the pipe. There are various national and international Pipe Color Code Standards are available. (I have used both British and American version to spell color/colour)

- ASME/ANSI A13.1 – Scheme for the Identification of Piping Systems

- BS 1710 – Specification for Identification of Pipelines and Services

- IS 2379 – Pipelines Identification Colour Code

- PFI ES-22 – Recommended Practice for Color Coding of Piping Materials

Color Coding of Piping Material – PFI ES-22

Why the color coding of piping material?

During construction and fabrication, various grades of carbon steel, alloy steel, and stainless steel are used. To avoid mixing of this material and easy storing and retrieving in the warehouse, piping components such as pipe, fittings, flanges, and valves are color coded.

All most all company has their own color coding system. Pipe Fabrication Institute (PFI) Standard ES-22 provides Piping Materials color coding requirements for most commonly used piping material grades. It also provides guidance on marking location on piping components.

Refer below images for the color band location on piping components.

Color Code for Pipe Material Identification – PFI Standard ES-22 -1999

Carbon Steel Material

| Carbon Steel | ||

|---|---|---|

| Material | Material Garde | Band / Strip Color |

| Carbon Steel, Electric Resistance Welded Pipe | A53 Gr. B/API | 1 solid white |

| Carbon Steel, Smls, specified tensile strength under 70,000 psi (483 MPA) | A53 Gr. B | No Marking |

| Carbon Steel, killed steel | A106 Gr. B | 1 solid green |

| Carbon Steel, specified tensile strength 70,000 psi (483 MPA) and over | A106 Gr. C | 2 solid green |

| Carbon Steel, low temperature (impact tested) | A333 Gr. 6 | 1 solid red |

High Yield Carbon Steel

| High Yield Carbon Steel | ||

|---|---|---|

| Material | Material Garde | Band / Strip Color |

| 52,000 min. yield | API 5L X-52 | 1 solid yellow, 1 solid green |

| 60,000 min. yield | API 5L X-60 | 1 solid yellow, 1 solid pink |

| 65,000 min. yield | API 5L X-65 | 2 solid yellow |

| 70,000 min. yield | API 5L X-70 | 1 solid yellow, 1 solid orange |

Low Alloy Materials

| Low Alloy Materials | ||

|---|---|---|

| Material | Material Garde | Band / Strip Color |

| C-Mo steel | A335 Gr. P1 | 1 solid orange |

| 1 Cr-1/2 Mo Steel | A335 Gr. P12 | 1 solid orange, 1 solid blue |

| 1 1 /4 Cr-1/2 Mo Steel | A335 Gr. P11 | 1 solid yellow |

| 2 1/4 Cr-1 Mo Steel | A335 Gr. P22 | 1 solid blue |

| 5 Cr-1/2 Mo Steel | A335 Gr. P5 | 1 solid blue, 1 solid yellow |

| 9 Cr-1/2 Mo Steel | A335 Gr. P9 | 2 solid orange |

Ferritic and Martensitic Stainless Steels

| Ferritic and Martensitic Stainless Steels | ||

|---|---|---|

| Material | Material Garde | Band / Strip Color |

| Type 405 | A268 TP405 | 1 solid green, 1 solid black |

| Type 410 | A268 TP410 | 1 solid green, 1 solid red |

Austenitic Stainless Steels

| Austenitic Stainless Steels | ||

|---|---|---|

| Material | Material Garde | Band / Strip Color |

| Type 304 | A312 TP304 | 1 solid black |

| Type 304L | A312 TP304L | 2 solid black |

| Type 304H | A312 TP304H | 1 intermittent black |

| Type 309 | A358 Gr309 | 1 solid black, 1 solid brown |

| Type 310 | A358Gr310 | 1 solid green, 1 solid orange |

| Type 316 | A312 TP316 | 1 solid gray |

| Type 316L | A312 TP316L | 2 solid gray |

| Type 316H | A312 TP316H | 1 intermittent gray |

| Type 317 | A312 TP317 | 1 solid brown, 1 solid green |

| Type317L | A312 TP317L | 1 solid brown, 1 solid red |

| Type 321 | A312 TP321 | 1 solid pink |

| Type 321 H | A312 TP321H | 2 solid pink |

| Type 347 | A312 TP347 | 1 solid brown |

| Type 347H | A312 TP347H | 2 solid brown |

Nickel Based Alloys

| Nickel Based Alloys | |

|---|---|

| Material | Band / Strip Color |

| Nickel 200 | 1 solid black, 1 solid pink |

| Incoloy 800 | 1 solid black, 1 solid orange |

| Incoloy 800H | 1 solid gray, 1 solid red |

| Incoloy 825 | 1 solid gray, 1 solid blue |

| Inconel 600 | 2 solid blue |

| Inconel 625 | 1 solid blue, 1 solid pink |

| Hastelloy Alloy 8-2 | 1 solid red, 1 solid orange |

| Hastelloy Alloy C-276 | 1 solid red, 1 solid blue |

| Hastelloy Alloy C-22 | 2 solid red |

| Hastelloy Alloy G | 1 solid red, 1 solid yellow |

| Carpenter Alloy 20 C 8-3 | 1 solid black, 1 solid blue |

| Monel 400 | 1 solid black, 1 solid yellow |

Color Coding of Pipeline and Piping Identification

Oil and Gas Industries, Process industries are complex installation. Piping systems are used in these plants to transport various fluids. These pipelines transport various industrial materials such as gases such as Air, Nitrogen, Oxygen, Hydrogen, etc., liquids such as water, acids, hydrocarbon, toxic materials, etc.

Without proper pipe color code, it is extremely difficult to identify the material pipeline transporting. To reduces the safety hazard, reduce the possibility of mistakes in identification and accidents associated with the wrong identification of pipelines during the emergency situation, systematic color coding of pipelines and piping systems is essential. Uniformity of color marking promotes greater safety, lessens the chances of error, and reduces hazards involved in the handling of material inside the pipelines.

There are national and international standards that provide the guidelines for uniform color coding in industries that are used to color code of pipe to identify.

- ASME A13.1 – Scheme for the Identification of Piping Systems

- BS 1710 – Specification for Identification of Pipelines and Services

- IS 2379 – Pipelines Identification Colour Code

These standard uses different color code methodology to identify the pipe material. They use a base color, band color, letters, and direction arrow to identify fluid inside the pipeline.

ANSI/ASME A13.1 – Scheme for the Identification of Piping Systems

The purpose of ASME/ANSI A13.1 Standard is to establish a common system that assists in the identification of hazardous materials conveyed in piping systems and their hazards when released into the environment.

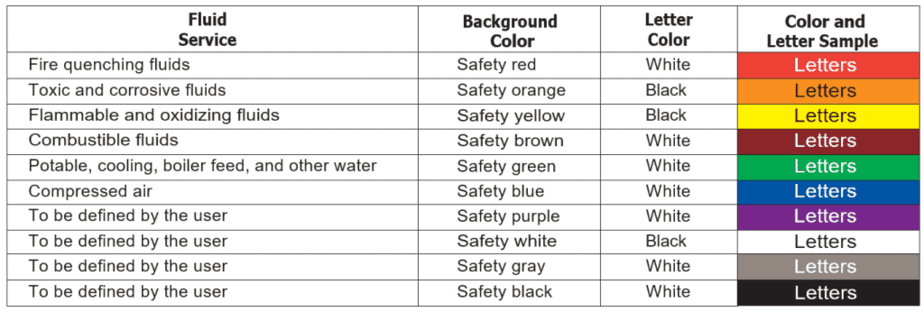

ASME A13.1 – 2015 edition has six fixed colors and 4 users define colors that can be used to identify the hazardous material. In this standard, the following categories are used;

- Flammable – Fluids or vapor or produce vapors that can be ignited and continue to burn in air.

- Combustible – Fluids that can burn, but are not flammable.

- Oxidizing – Oxidizing fluid is any gas or liquid that may, generally by providing oxygen, cause or contribute to the combustion of other material more than air does.

- Toxic and Corrosive – Fluids that are corrosive or toxic, or will produce corrosive or toxic substances when released.

- Fire Quenching – Fluid Such as water, foam, and CO2 used in sprinkler systems and firefighting piping systems.

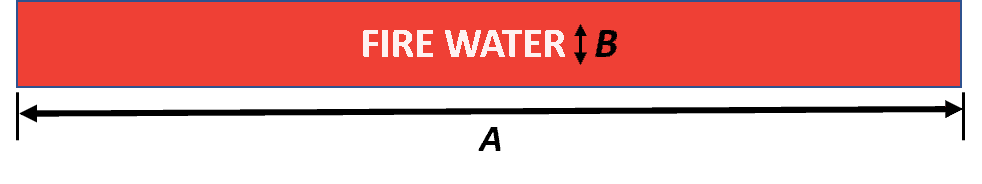

Size of Label and Letters as per ASME B13.1-2015

| Outside Diameter of Pipe in Inches | Outside Diameter of Pipe in mm | Length of Color Field, A, in Inches | Length of Color Field, A, in mm | Size of Letters, B, in Inches | Size of Letters, B, in mm |

|---|---|---|---|---|---|

| 3⁄4 to 11⁄4 | 19 to 32 | 8 | 200 | 1⁄2 | 13 |

| 11⁄2 to 2 | 38 to 51 | 8 | 200 | 3⁄4 | 19 |

| 21⁄2 to 6 | 64 to 150 | 12 | 300 | 11⁄4 | 32 |

| 8 to 10 | 200 to 250 | 24 | 600 | 21⁄2 | 64 |

| Over 10 | over 250 | 32 | 800 | 31⁄2 | 89 |