Din 906 Plug | Din 906 Locking Screws | Din 906 Screw Plug | Din 906 Hexagonal Socket Pipe Plug

Socket Screw Plug

Threaded Plug

Hexagonal Socket Plug

Din 906 Plug Suppliers | Din 906 Threaded Plug Manufacturer

Mumbadevi Steel India (MSI) Metals & Tubes is widely popular as DIN 906 Plug Suppliers all over the globe. We supply DIN 906 Threaded Plugs also known by various names such as Din 906 Socket Screw Plugs, Din 906 Locking Screw Plug, Din 906 Tapered Plugs, Din 906 Hexagonal Sockets, etc.

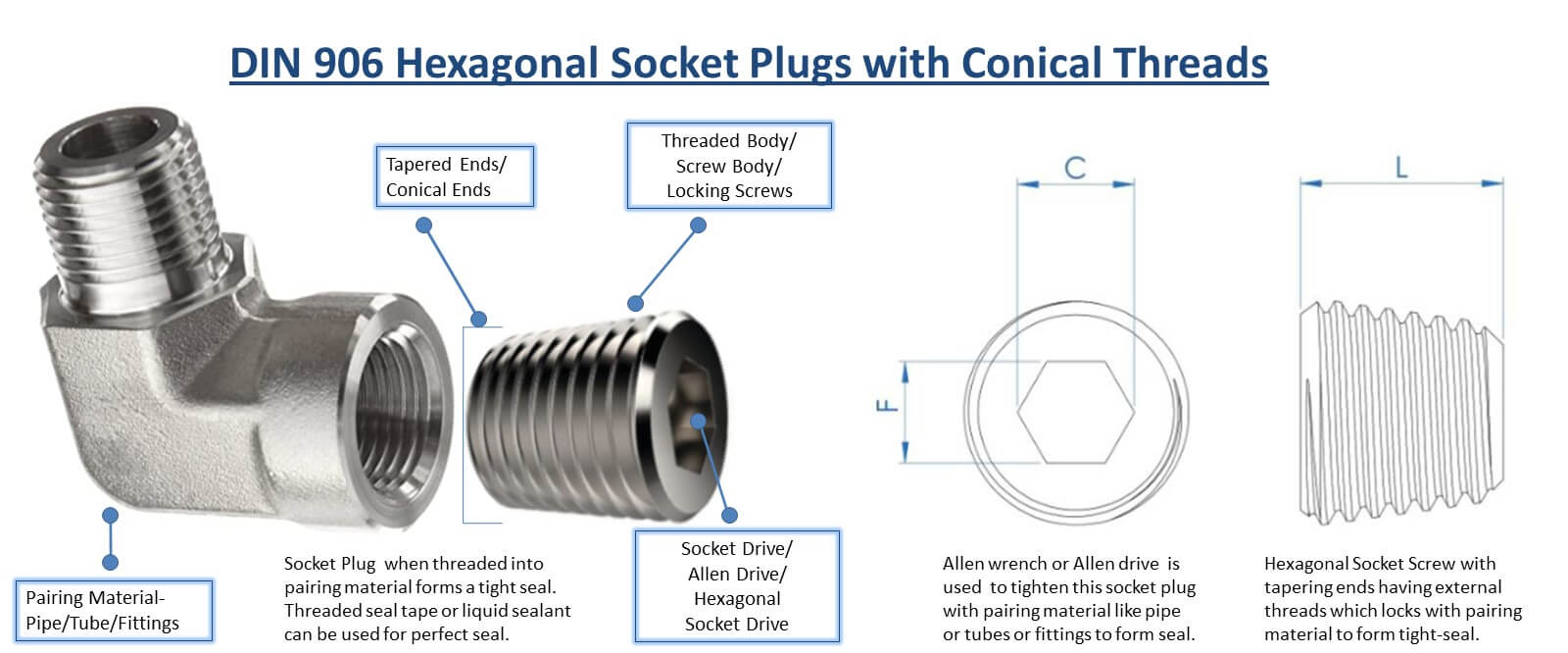

Stainless Steel DIN 906 Plugs are exclusively used or applicable to seal bore holes or close pipe holes with cylindrical external threads, and hence also known as Din 906 Socket Pipe Plugs. These din 906 plugs are tapered hexagonal socket threaded screw plugs from outside with Allen drive (hexagonal socket drive) at top inner side. Hence also know as Din 906 Hexagonal Socket Plug. This plug has tapered pipe thread all over its length and hence known as Din 906 Tapered Plugs.

Din 906 Plugs are exclusively used to form a seal in pipes and pipe fittings with cylindrical threaded holes which are generally used to carry high pressure fluid, gasses or air within them. The Threaded section of Din 906 Plugs is slightly tapered or conical at one end. When the plug is tightened inside the pipe with appropriate torque using Allen drive wrench or key, the deformation in the threads of plugs creates a tight seal. The tightness of these plugs varies and is dependent on factors like pressure, temperature, medium, and the material used for pairing. Seal coating agents are applied make it even more perfect seal like threaded seal tape also known as Teflon tape, a liquid pipe sealant is applied on threads, etc. DIN 906 Screw Plugs are available in steel and stainless steel A2 and A4 grades with type A (without micro encapsulation) and type GPC (with micro encapsulation). Higher degree of safety is achieved in the design with GPC thread coating.

At our company, Mumbadevi Steel India (MSI) Metals & Tubes, the following sizes of DIN 906 tapered plugs are available for instant shipping from stock with diameters ranging from M8 to M48 in steel and stainless steel A2 and A4. We also provide DIN 906 standard sheet for thread sizes M33x2, M38x1.5, M39x2, M52x1.5, M52x2, M56x2 and M60x2.

Din 906 Plug Supplier Stockist

Mumbadevi Steel India (MSI) is Certified and CRISIL MSE 4 Rated company from India. We export best quality Din 906 in Nickel Alloy, Stainless Steel, Inconel, Hastelloy etc grades finished according to standards and specifications. Contact for best price on Din 906 Locking Screws. Mumbadevi Steel India (MSI) can supply the Din 906 Screw Plug. Din 906 Plug comes in many different materials such as Inconel Din 906 Plug, Incoloy Din 906 Plug, Monel Din 906 Plug, Hastelloy Din 906 Plug, SS Din 906 Plug, Titanium Din 906 Plug, Duplex 2205 Din 906 Plug, Super Duplex Din 906 Plug, Copper Nickel Din 906 Plug, Alloy 20 Din 906 Plug, SS 904L Din 906 Plug Alloy 200 Din 906 Plug, 254 SMO Din 906 Plug, Brass Din 906 Plug, AISI 4130 Din 906 Plug, SS Din 906 Plug.

Technical specifications:

- Size (inch): 1/8" to 2", M8 to M50

- Driving Features: Hexagonal Socket.

- Material: Stainless Steel/ Alloy Steel.

- Thread Direction: Right.

- Surface Treatment: Plain.

- Thread: Taper Pipe Thread.

- Din: 906.

Additional specifications:

-

Types:

- Type A: without micro encapsulation

- Type GPC: with micro encapsulation

-

Version in Steel ST:

- ultrasonically and tensile tested

- zinc plated, blue passivated

Ready to Dispatch Stock at Best Price, Warehouse near to Airport and Port for Fast Delivery. Contact Us Today !

Why are these plugs known by various names??

Even if Din 906 Plug is known by various names in the industry, yet they are all same and are used for same purpose that is to create a seal with the pairing material. Below are certain names by which they are known by and a short description defining why that name is affiliated with din 906 plugs

Din 906 Socket Screw Plug - These plugs have body similar to that of screws with socket drive to tighten them with the pairing material to form a tight-seal. Hence they are also known as din 906 socket screw plug.

Din 906 Threaded Plugs - These plugs have body similar to that of screws with pipe threads around it along with socket drive to tighten them with the pairing material to form a tight-seal. Hence they are also known as din 906 threaded plug.

Din 906 Locking Screws - These plugs are attached to one end of pipes, bores or fittings which carry various content (fluids, gasses) within them. These plugs create a locked-seal so there is no leakage of the content which remains well protected inside. Hence they are also known as din 906 locking plug.

Din 906 Screw Plugs - These plugs have body similar to that of screws with socket drive to tighten them with the pairing material to form a tight-seal. Hence they are also known as din 906 screw plug.

Din 906 Socket Pipe Plugs - These plugs have body similar to that of screws with socket drive to tighten them with the pairing material to form a tight-seal. They are used in association with pipes to create seal to stop the flow of content within. Socket format helps to save space and when tightened, the threads create a tight- seal with pipes. Hence they are also known as din 906 socket pipe plugs.

Din 906 Hexagonal Socket Pipe Plugs or Din 906 Hexagonal Sockets These plugs have body similar to that of screws with socket drive to tighten them with the pairing material to form a tight-seal. They are used in association with pipes to create seal to stop the flow of content within. Socket format is in hexagonal shape which is tightened with help of allen wrench. When tightened, the threads create a tight- seal with pipes. Hence they are also known as din 906 hexagonal socket pipe plugs. Or din 906 hexagonal sockets.

Din 906 Plugs- These are used with pipes, bores and fittings to stop the flow of content within by creating a tight-seal. Hence they are known as Din 906 plugs.

Din 906 Tapered Plugs - These plugs have tapered or a conical end which helps the plug to fit within the pairing material, thereby creating a tight-seal. Hence they are known as Din 906 tapered plugs or Din 906 conical plugs.

Mechanical Properties of Din 906 Locking Screws-

Austenitic nature stainless steel is by far the most common type used with strength grades designated by sequence of alphabets with number, for eg- A2.

| Steel Group | Steel Grade | Strength Class | Screws. Nuts and Bolts | |||

|---|---|---|---|---|---|---|

| Tensile strength N/mm2 | Tensile strength PSI | Dia range | Nut Load N/mm2 | |||

| Austenitic | A2 and A4 | 50 | 500 | 70.000 | ≤M39 | 500 |

| 70 | 700 | 100.000 | ≤M20 | 700 | ||

| 80 | 800 | 118.000 | ≤M20 | 800 | ||

| Steel Group | Property Strength Class | Made From |

|---|---|---|

| Austenitic | 50 | A1.A2 |

| 70 | A2.A4 | |

| 80 | A2.A4 |

Chemical Composition Of DIN 906 Tapered Plug

| Grade | USA Grade | Material Designation | Material NO. | C % | Si ≤% | Mn ≤% | Cr % | Mo % | Ni % |

|---|---|---|---|---|---|---|---|---|---|

| A2 | 304 | X 5 Cr Ni 1810 | 1.4301 | ≤0.07 | 1.0 | 2.0 | 17.5 to 19.5 | - | 8.0 to 10.5 |

| X 2 Cr Ni 1811 | 1.4306 | ≤0.03 | 1.0 | 2.0 | 18.0 to 20.0 | - | 10.0 to 12.0 | ||

| X 8 Cr Ni 19/10 | 1.4303 | ≤0.07 | 1.0 | 2.0 | 17.0 to 19.0 | - | 11.0 to 13.0 | ||

| A4 | 316 | X 5 Cr Ni MO 1712 | 1.4401 | ≤0.07 | 1.0 | 2.0 | 16.5 to 18.5 | 2.0-2.5 | 10.0 to 13.0 |

| X 2 Cr Ni MO 1712 | 1.4404 | ≤0.03 | 1.0 | 2.0 | 16.5 to 18.5 | 2.0-2.5 | 10.0 to 13.0 |

| Property Class | Material And Treatment | Chemical Composition Limits % | Tempering Temp ºc Min | |||

|---|---|---|---|---|---|---|

| C | P | S | ||||

| min | max | max | max | |||

| 4.6. 4.8. 5.8. 6.8 | Low or medium carbon steel | - | 0.55 | 0.05 | 0.06 | - |

| 8.8 | Medium carbon steel quenched. tempered | 0.25 | 0.55 | 0.04 | 0.05 | 425 |

| 9.8 | Medium carbon steel quenched. tempered | 0.25 | 0.55 | 0.04 | 0.05 | 425 |

| 10.9 | Medium carbon steel additives | 0.20 | 0.55 | 0.04 | 0.05 | 425 |

| 12.9 | Alloy steel - quenched. tempered | 0.20 | 0.50 | 0.035 | 0.035 | 380 |

Chemical Composition of DIN 906 Tapered Hexagon Socket Screw Plug

| Mechanical Property | Property Class | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 4.8 | 5.6 | 5.8 | 6.8 | 8.8 | 9.8 | 10.9 | 12.9 | |||

| Up to M16 | Up to M16 | |||||||||

| Tensile Strength (Rm. N/mm²) | nom | 400 | 500 | 600 | 800 | 900 | 1000 | 1200 | ||

| min. | 420 | 500 | 520 | 600 | 800 | 830 | 900 | 1040 | 1220 | |

| Vickers Hardness | min. | 130 | 155 | 160 | 190 | 250 | 255 | 290 | 320 | 385 |

| max. | 250 | 320 | 336 | 360 | 380 | 435 | ||||

| Brinell Hardness | min | 124 | 147 | 152 | 181 | 319 | 242 | 266 | 295 | 353 |

| max. | 238 | 385 | 319 | 342 | 363 | 412 | ||||

| Rockwell Hardness | min. HR | 71 | 79 | 82 | 89 | - | ||||

| HRC | - | - | - | - | 20 | 23 | 28 | 32 | 39 | |

| HR | 95 | 99 | - | |||||||

| max. HRC | - | - | - | - | 32 | 34 | 37 | 37 | 44 | |

| Yield Stress ReL.N/mm² | nom. | 320 | 300 | 400 | 480 | - | ||||

| min. | 340 | 300 | 420 | 480 | - | |||||

| Stress at permanent set limit N/mm² | nom. | - | 640 | 720 | 900 | 1080 | ||||

| min. | - | 640 | 660 | 720 | 940 | 1100 | ||||

Din 906 Plugs Available In Following Grades

- Inconel 600 Din 906 Socket Screw Plug

- Inconel 601 Din 906 Socket Screw Plug

- Inconel 625 Din 906 Socket Screw Plug

- Inconel 718 Din 906 Socket Screw Plug

- Incoloy 800 Din 906 Socket Screw Plug

- Incoloy 800H Din 906 Socket Screw Plug

- Incoloy 800HT Din 906 Socket Screw Plug

- Incoloy 825 Din 906 Socket Screw Plug

- Monel 400 Din 906 Socket Screw Plug

- Monel K500 Din 906 Socket Screw Plug

- Hastelloy B2 Din 906 Socket Screw Plug

- Hastelloy C22 Din 906 Socket Screw Plug

- Hastelloy C276 Din 906 Socket Screw Plug

- Stainless Steel 304 Din 906 Socket Screw Plug

- Stainless Steel 304L Din 906 Socket Screw Plug

- Stainless Steel 304H Din 906 Socket Screw Plug

- Stainless Steel 316L Din 906 Socket Screw Plug

- Stainless Steel 316H Din 906 Socket Screw Plug

- Stainless Steel 316Ti Din 906 Socket Screw Plug

- Stainless Steel 321 Din 906 Socket Screw Plug

- Stainless Steel 321H Din 906 Socket Screw Plug

- Stainless Steel 347 Din 906 Socket Screw Plug

- Stainless Steel 347H Din 906 Socket Screw Plug

- Stainless Steel 904L Din 906 Socket Screw Plug

- Stainless Steel 309 Din 906 Socket Screw Plug

- Stainless Steel 310 Din 906 Socket Screw Plug

- Stainless Steel 317L Din 906 Socket Screw Plug

- Stainless Steel 330 Din 906 Socket Screw Plug

- Titanium Grade 1 Din 906 Socket Screw Plug

- Titanium Grade 2 Din 906 Socket Screw Plug

- Inconel 600 Din 906 Threaded Plug

- Inconel 601 Din 906 Threaded Plug

- Inconel 625 Din 906 Threaded Plug

- Inconel 718 Din 906 Threaded Plug

- Incoloy 800 Din 906 Threaded Plug

- Incoloy 800H Din 906 Threaded Plug

- Incoloy 800HT Din 906 Threaded Plug

- Incoloy 825 Din 906 Threaded Plug

- Monel 400 Din 906 Threaded Plug

- Monel K500 Din 906 Threaded Plug

- Hastelloy B2 Din 906 Threaded Plug

- Hastelloy C22 Din 906 Threaded Plug

- Hastelloy C276 Din 906 Threaded Plug

- Stainless Steel 304 Din 906 Threaded Plug

- Stainless Steel 304L Din 906 Threaded Plug

- Stainless Steel 304H Din 906 Threaded Plug

- Stainless Steel 316L Din 906 Threaded Plug

- Stainless Steel 316H Din 906 Threaded Plug

- Stainless Steel 316Ti Din 906 Threaded Plug

- Stainless Steel 321 Din 906 Threaded Plug

- Stainless Steel 321H Din 906 Threaded Plug

- Stainless Steel 347 Din 906 Threaded Plug

- Stainless Steel 347H Din 906 Threaded Plug

- Stainless Steel 904L Din 906 Threaded Plug

- Stainless Steel 309 Din 906 Threaded Plug

- Stainless Steel 310 Din 906 Threaded Plug

- Stainless Steel 317L Din 906 Threaded Plug

- Stainless Steel 330 Din 906 Threaded Plug

- Titanium Grade 1 Din 906 Threaded Plug

- Titanium Grade 2 Din 906 Threaded Plug

- Inconel 600 Din 906 Hexagonal Socket Plug

- Inconel 601 Din 906 Hexagonal Socket Plug

- Inconel 625 Din 906 Hexagonal Socket Plug

- Inconel 718 Din 906 Hexagonal Socket Plug

- Incoloy 800 Din 906 Hexagonal Socket Plug

- Incoloy 800H Din 906 Hexagonal Socket Plug

- Incoloy 800HT Din 906 Hexagonal Socket Plug

- Incoloy 825 Din 906 Hexagonal Socket Plug

- Monel 400 Din 906 Hexagonal Socket Plug

- Monel K500 Din 906 Hexagonal Socket Plug

- Hastelloy B2 Din 906 Hexagonal Socket Plug

- Hastelloy C22 Din 906 Hexagonal Socket Plug

- Hastelloy C276 Din 906 Hexagonal Socket Plug

- Stainless Steel 304 Din 906 Hexagonal Socket Plug

- Stainless Steel 304L Din 906 Hexagonal Socket Plug

- Stainless Steel 304H Din 906 Hexagonal Socket Plug

- Stainless Steel 316L Din 906 Hexagonal Socket Plug

- Stainless Steel 316H Din 906 Hexagonal Socket Plug

- Stainless Steel 316Ti Din 906 Hexagonal Socket Plug

- Stainless Steel 321 Din 906 Hexagonal Socket Plug

- Stainless Steel 321H Din 906 Hexagonal Socket Plug

- Stainless Steel 347 Din 906 Hexagonal Socket Plug

- Stainless Steel 347H Din 906 Hexagonal Socket Plug

- Stainless Steel 904L Din 906 Hexagonal Socket Plug

- Stainless Steel 309 Din 906 Hexagonal Socket Plug

- Stainless Steel 310 Din 906 Hexagonal Socket Plug

- Stainless Steel 317L Din 906 Hexagonal Socket Plug

- Stainless Steel 330 Din 906 Hexagonal Socket Plug

- Titanium Grade 1 Din 906 Hexagonal Socket Plug

- Titanium Grade 2 Din 906 Hexagonal Socket Plug