70 30 CuNi Wire Mesh

Mumbadevi Steel India (MSI) offers all types of Copper Nickel Wiremesh in multiple sizes and forms. We are Certified Company with exports in 70 countries. Contact u for best price.

Other Names: Copper Nickel Wire, Copper Nickel mesh, Copper Nickel wire mesh

Material: 70 30 CuNi

Brand: Mumbadevi Steel India (MSI)

Manufacturer: Mumbadevi Steel India (MSI)

70 30 CuNi Wire • 70 30 CuNi Wire Mesh Suppliers • Copper Nickel Welded Wire Mesh • Copper Nickel Woven Wire Mesh

Mumbadevi Steel India (MSI) is a suppliers of Copper Nickel Wiremesh. We stock all types of CuNi Wiremeshes and CuNi Wires. Contact us for best price.

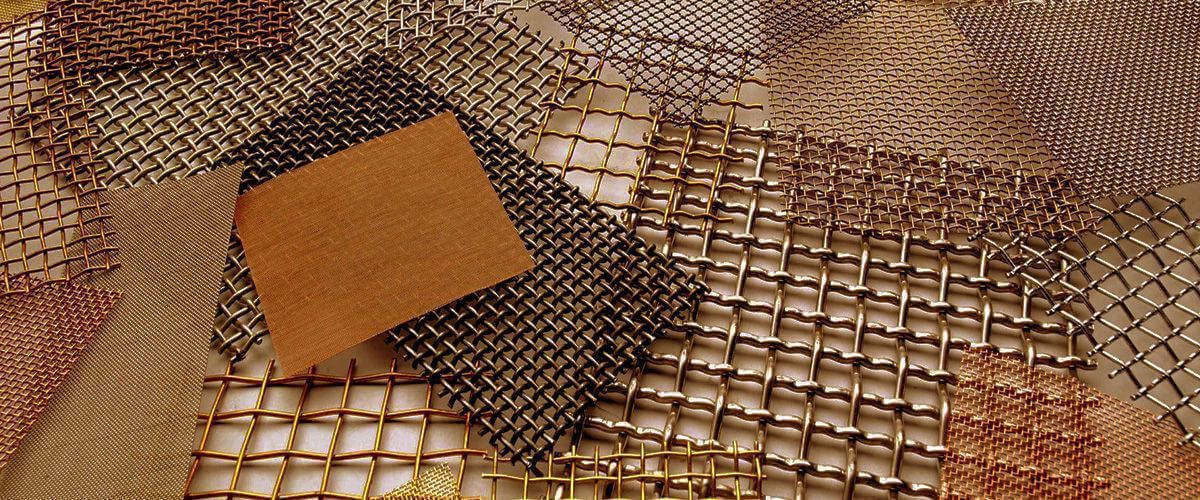

A Wire is a metal drawn out into the form of a thin flexible thread or rod. Mesh is similar to a net in that it has many attached woven or welded strands. Wire mesh is a metallic product that is used across a wide spectrum of applications all over the world. Wire Mesh is a grid formed by welding steel wires together at their intersections. Wire mesh is available in different sizes and types, and each different mesh design can be comprised of varying metals and alloys. Copper Nickel Wire Mesh is further classified as Welded Wire Mesh and Woven Wire Mesh.

Copper Nickel Welded Wire Mesh is a grid formed by welding steel wires together at their intersections. Welded steel wire mesh offers greater strength and versatility over woven mesh. Welded mesh will not fray or unravel, is stable and rigid, has a smooth surface and has an excellent aesthetic appearance. Available in a wide range of wire diameters and opening sizes. Copper Nickel Woven Wire Mesh is a grid formed by weaving wires alternately over and under and are lock-crimped at their intersections. Woven wire mesh is stable and rigid, has a smooth surface and is aesthetically pleasing. Available in a wide range of wire diameters and opening sizes. Copper Nickel Woven Wire Mesh are further classified into Plain Weave Wire Mesh, Twill Weave Wire Mesh, Dutch Weave Wire Mesh, Crimped Weave Wire Mesh, Three Heddled Weave Wire Mesh, Five Heddled Weave Wire Mesh, Plain Dutch Wire Mesh, Dutch Twill Weave, Twill Dutch Weave, Reverse Dutch Wire Mesh, Reverse Twill Dutch Wire Mesh, Cross Twill Weave.

Mumbadevi Steel India (MSI) is the market leader in the production of Copper Nickel wiremesh of welded and woven types. CuNi wire mesh has varied applications in construction, food processing, automobile, mining, etc. We have the capacity to manufacture meshes with wires from 1,2 to 12 mm and of any aperture, square or rectangular. The wire mesh we supply conforms to ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360 specifications. The thickness of wire mesh is 10 mm To 100 mm Diameter in 100 mm TO 6000 mm in Length. Wire mesh is used in a wide variety of industries since it is one of the most common materials for woven wire mesh products besides mild steel and galvanised steel with different properties. Some common applications for wire meshes are for instance industrial sieves, chemical filters, architectural decoration, dandy roll sleeves for paper making, dryer belts and conveyor belts for the non-food industry as well as for the food industry.

Mumbadevi Steel India (MSI) have been supplying wire mesh globally since many years. We have exported our products to countries such as UAE, Qatar, USA, Europe, Thailand, South Africa, Japan, Indonesia, Russia, UK, Norway, etc. We have a good reputation amongst all our international clients.

- Wiremesh Specification: ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360, EN 12164 & DIN 2.9882

- Thickness Range: 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length

- Type: Wiremesh & Wire

- Form: 70 30 CuNi Plain Weave, 70 30 CuNi Twill Weave, 70 30 CuNi Dutch Weave, 70 30 CuNi Plain Dutch Wire Mesh, 70 30 CuNi Dutch Twill Weave, 70 30 CuNi Twill Dutch Weave, 70 30 CuNi Reverse Dutch Wire Mesh, 70 30 CuNi70 30 CuNi Reverse Twill Dutch Wire Mesh, 70 30 CuNi Cross Twill Weave

- Surface Finish: Mill Finish, PTFE Coating

- Origin: Indian Origin, European Origin, Japanese Origin

- Testing and Documents: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

- Packing: Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

70 30 CuNi Alloy Wiremesh Sizes in Stock

| Type of Wiremesh | Thickness |

|---|---|

| Copper Nickel Plain Weave, Copper Nickel Twill Weave, Copper Nickel Dutch Weave, Copper Nickel Plain Dutch Wire Mesh, Copper Nickel Dutch Twill Weave, Copper Nickel Twill Dutch Weave, Copper Nickel Reverse Dutch Wire Mesh, Copper Nickel Reverse Twill Dutch Wire Mesh, Copper Nickel Cross Twill Weave & Copper Nickel Wire | 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length |

Forms of UNS C71500 in Stock

Wire

70 30 CuNi Wire Available in 10 mm To 100 mm Dia

Mesh

70 30 CuNi Mesh Available in 10 mm To 100 mm Dia

Welded Wire Mesh

70 30 CuNi Welded Wire Mesh Available in 10 mm To 100 mm Dia

Woven Wire Mesh

70 30 CuNi Woven Wire Mesh Available in 10 mm To 100 mm Dia

Plain Weave Wire Mesh

70 30 CuNi Plain Weave Wire Mesh Available in 10 mm To 100 mm Dia

Twill Weave Wire Mesh

70 30 CuNi Twill Weave Wire Mesh Available in 10 mm To 100 mm Dia

Dutch Weave Wire Mesh

70 30 CuNi Dutch Weave Wire Mesh Available in 10 mm To 100 mm Dia

Crimped Weave Wire Mesh

70 30 CuNi Crimped Weave Wire Mesh Available in 10 mm To 100 mm Dia

Three Heddled Weave Wire Mesh

70 30 CuNi Three Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

Five Heddled Weave Wire Mesh

70 30 CuNi Five Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

-

Chemical Properties

-

Mechanical Properties

-

Physical Properties

-

Cu Pb Mn Fe Zn Ni MIN 65.000 - - 0.400 - 29.000 MAX 0.500 1.000 1.000 1.000 33.000 -

Yield Strength

0.2% Proof

(MPa)Tensile strength

(MPa)Elongation

(% in 50mm)Hardness

(HRB)MIN 88 372 45.00 MAX 483 517 51 -

Density kg/dm³ 8.95 Melting Range °C 1170-1240 Specific Heat J/kg °K 377 Thermal Conductivity W/m°K 29 Coeff. of Linear Expansion 10-300°C" 10-6/°K 16 Electrical Resistivity microhm. cm 34 Modulus of Elasticity GPa 152 Modulus of Rigidity GPa 56

Properties of 70 30 CuNi alloy

70 30 Copper-Nickel Cold Forming and Hot Forming

With good hot and cold working properties, copper nickel alloy responds well to most fabrication processes. Due to properties inherited from Copper, Copper-Nickel alloy is can be easily drawn and spin.

70 30 Copper-Nickel Machining

Copper-nickels can be cut using most conventional cutting processes. Plasma-arc cutting is fast, accurate and economical. Laser and abrasive water jet cutting are also possible The machinability rating of 70 30 copper-nickel alloy is 20%.

70 30 CuNi Welding

Copper Nickel Alloys can be easily joined by soldering, brazing and a variety of welding methods such as gas shielded arc welding, spot welding, coated metal arc welding, butt welding, seam welding, brazing, soldering and oxyacetylene welding processes.

70 30 CuNi Corrosion Resistance

Copper-nickel Alloys have good resistance to chloride pitting and crevice corrosion. They have excellent corrosion resistance against moisture, non-oxidising acids, alkalis and salt solutions, organic acids and to gases such as oxygen, chlorine, hydrogen chloride, hydrogen fluoride, sulphur dioxide and carbon dioxide. It is found that the corrosion rates of CuNi alloys are 0.02-0.002mm/year in sea-water.

Services We Offer

Documentation

Documentation is a very important part of the products we supply, and we work continuously to enhance the efficiency of the document-handling process without compromising quality of the product. Documents provided along with the shipment include Certificate of Origin, Material Test Certificate as per EN 10204 3.1 and 10204 3.2, NACE MR10103 and NACE MR0175 certified Test Certificates.

Quality Assurance

Copper Nickel Wiremesh are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Packing and Delivery

The product is wrapped and packed in wooden crates or carton boxes. Our primary goal is to deliver quality products in time, no matter where the client is located.