Hastelloy C276 Wire Mesh

Mumbadevi Steel India (MSI) is a leading suppliers and exporter of Hastelloy C276 Wire Mesh. The company is ISO 9001:2015 Certified and CRISIL MSE 4 Rated. We have served more than 50 clients worldwide.

Other Names: Hastelloy Wire, Hastelloy mesh, Hastelloy wire mesh

Material: Hastelloy C276

Brand: Mumbadevi Steel India (MSI)

Manufacturer: Mumbadevi Steel India (MSI)

Hastelloy C276 Wire • Hastelloy C276 Wire Mesh Suppliers • Hastelloy Welded Wire Mesh • Hastelloy Woven Wire Mesh

Hastelloy C276 Wire Mesh is supplied by Mumbadevi Steel India (MSI) at reasonabe prices. We are a global exporter of UNS N10276 Wire Mesh. With almost 50 years in the business, we can offer the finest expertise to build practically any type of metal, alloys or steel. All of our manufactured products are subject to the rigirous audit process, which allow us to deliver quality products that meet customer requirements at low cost

A Wire is a metal drawn out into the form of a thin flexible thread or rod. Mesh is similar to a net in that it has many attached woven or welded strands. Wire mesh is a metallic product that is used across a wide spectrum of applications all over the world. Wire Mesh is a grid formed by welding steel wires together at their intersections. Wire mesh is available in different sizes and types, and each different mesh design can be comprised of varying metals and alloys. Hastelloy Wire Mesh is further classified as Welded Wire Mesh and Woven Wire Mesh.

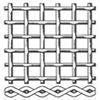

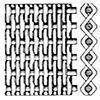

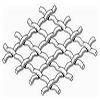

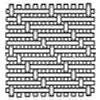

Hastelloy Welded Wire Mesh is a grid formed by welding steel wires together at their intersections. Welded steel wire mesh offers greater strength and versatility over woven mesh. Welded mesh will not fray or unravel, is stable and rigid, has a smooth surface and has an excellent aesthetic appearance. Available in a wide range of wire diameters and opening sizes. Hastelloy Woven Wire Mesh is a grid formed by weaving wires alternately over and under and are lock-crimped at their intersections. Woven wire mesh is stable and rigid, has a smooth surface and is aesthetically pleasing. Available in a wide range of wire diameters and opening sizes. Hastelloy Woven Wire Mesh are further classified into Plain Weave Wire Mesh, Twill Weave Wire Mesh, Dutch Weave Wire Mesh, Crimped Weave Wire Mesh, Three Heddled Weave Wire Mesh, Five Heddled Weave Wire Mesh, Plain Dutch Wire Mesh, Dutch Twill Weave, Twill Dutch Weave, Reverse Dutch Wire Mesh, Reverse Twill Dutch Wire Mesh, Cross Twill Weave.

Mumbadevi Steel India (MSI) is the market leader in the production of Hastelloy wire Mesh of welded and woven types. Stainless steel wire mesh has varied applications in construction, food processing, automobile, mining, etc. We have the capacity to manufacture meshes with wires from 1,2 to 12 mm and of any aperture, square or rectangular. The wire mesh we supply conforms to ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360 specifications. The thickness of wire mesh is 10 mm To 100 mm Diameter in 100 mm TO 6000 mm in Length. Stainless steel wire mesh is used in a wide variety of industries since it is one of the most common materials for woven wire mesh products besides mild steel and galvanised steel with different properties. Some common applications for stainless steel wire meshes are for instance industrial sieves, chemical filters, architectural decoration, dandy roll sleeves for paper making, dryer belts and conveyor belts for the non-food industry as well as for the food industry.

Mumbadevi Steel India (MSI) have been supplying wire mesh globally since many years. We have exported our products to countries such as UAE, Qatar, USA, Europe, Thailand, South Africa, Japan, Indonesia, Russia, UK, Norway, etc. We have a good reputation amongst all our international clients.

- Wire Mesh Specification: ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360

- Thickness Range: 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length

- Type: Wire Mesh & Wire

- Form: Hastelloy C276 Plain Weave, Hastelloy C276 Twill Weave, Hastelloy C276 Dutch Weave, Hastelloy C276 Plain Dutch Wire Mesh, Hastelloy C276 Dutch Twill Weave, Hastelloy C276 Twill Dutch Weave, Hastelloy C276 Reverse Dutch Wire Mesh, Hastelloy C276Hastelloy C276 Reverse Twill Dutch Wire Mesh, Hastelloy C276 Cross Twill Weave

- Surface Finish: Mill Finish, PTFE Coating

- Origin: Indian Origin, European Origin, Japanese Origin

- Testing and Documents: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

- Packing: Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

Hastelloy C276 Alloy Wire Mesh Sizes in Stock

| Type of Wire mesh | Thickness |

|---|---|

| Hastelloy Plain Weave, Hastelloy Twill Weave, Hastelloy Dutch Weave, Hastelloy Plain Dutch Wire Mesh, Hastelloy Dutch Twill Weave, Hastelloy Twill Dutch Weave, Hastelloy Reverse Dutch Wire Mesh, Hastelloy Reverse Twill Dutch Wire Mesh, Hastelloy Cross Twill Weave & Hastelloy Wire | 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length |

Forms of UNS N10276 in Stock

Wire

Hastelloy C276 Wire Available in 10 mm To 100 mm Dia

Mesh

Hastelloy C276 Mesh Available in 10 mm To 100 mm Dia

Welded Wire Mesh

Hastelloy C276 Welded Wire Mesh Available in 10 mm To 100 mm Dia

Woven Wire Mesh

Hastelloy C276 Woven Wire Mesh Available in 10 mm To 100 mm Dia

Plain Weave Wire Mesh

Hastelloy C276 Plain Weave Wire Mesh Available in 10 mm To 100 mm Dia

Twill Weave Wire Mesh

Hastelloy C276 Twill Weave Wire Mesh Available in 10 mm To 100 mm Dia

Dutch Weave Wire Mesh

Hastelloy C276 Dutch Weave Wire Mesh Available in 10 mm To 100 mm Dia

Crimped Weave Wire Mesh

Hastelloy C276 Crimped Weave Wire Mesh Available in 10 mm To 100 mm Dia

Three Heddled Weave Wire Mesh

Hastelloy C276 Three Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

Five Heddled Weave Wire Mesh

Hastelloy C276 Five Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

-

Chemical Properties

-

Mechanical Properties

-

Physical Properties

-

C W Mn Fe S Si Cr Ni Co Mo P V MIN - 3.000 - 4.000 - - 14.500 Bal - 15.000 - - MAX 0.010 4.500 1.000 7.000 0.030 0.080 16.500 2.500 17.000 0.040 0.035 -

Yield Strength0.2% Proof(MPa) Tensile strength(MPa) Elongation (% in 50mm) Hardness (HRB) MIN 283 690 40.00 - MAX - - - 100 -

Density lb/in³ 0.321 g/cm³ 8.89 Specific Heat Btu/lb•°F 0.102 J/kg•°C 427 Melting Range °F 2415-2500 °C 1325-1370 Thermal Conductivity Btu•in/ft²•h•°F 67.9 W/m•°C 427 Young's Modulus 103 ksi 29.8 GPa 205 Shear Modulus 103 ksi 11.4 GPa 79 Permeability 200 oersted (15.9 kA/m) 1.0002 Poisson's Ratio 0.307

Properties of Hastelloy C276 alloy

Hastelloy C276 Cold Forming

Annealed treatment is followed for every forming operations. For cold deformation at high-level, cold forming is done for the deformation process where cracking is a possibility because of mild forming. The cold forming process is used to restore the resistance to stress corrosion cracking. For most of the time, a solution anneal is recommended after the complete formed or annealed operation which helps to restore the material to its optimum condition and properties.

Hastelloy C276 Hot Forming

Hastelloy C276 can be hot-worked into various forms but they are more sensitive to the amounts and rates of hot-reduction with the austenitic stainless steels. During Hot working, all parameters should be taken into account. Special attention should be given to the temperature at which the alloy begins to melt. The high strengths of the Hastelloys at elevated temperature, their low thermal conductivity, and their hardening rate. Moreover, when the temperature is low in the hot working range of the metal, they are resistance to deformation is increased rapidly. So, while hot working practices that give heavy initial reduction followed by moderate final reductions, also with frequent re-heating gives the good result.

Hastelloy C276 Machining

Hastelloy C276 can be machined using conventional production methods at satisfactory rates. During the machining processes these alloys work harden rapidly, generate high heat during cutting, weld to the cutting tool surface and offer high resistance to metal removal because of their high shear strengths. Following are key points that should be considered during machining operations: Capacity, Tooling, Lubrication/Coolants, Drilling. The actual operating parameters are to serve only as a guide and are not to be taken as absolute values.

Hastelloy C276 Welding

Gas tungsten-arc welding, gas metal-arc welding, shielded metal-arc (coated electrode) welding, or resistance welding may be used. Minimum heat input consistent with adequate penetration reduces the chance of hot-cracking. Oxyacetylene welding should be avoided due to possibility of carburization. Hastelloy C-276 can be used in the as-welded condition in most chemical and petrochemical process equipment

Hastelloy C276 Heat Treatment

Wrought forms of Hastelloy C-276 are furnished in the solution heat-treated condition unless otherwise specified. Alloy C-276 is normally solution heat-treated at 2050 °F and rapid quenched. Parts which have been hot-formed should be solution heat-treated prior to final fabrication or installation, if possible

Services We Offer

Documentation

Documentation is a very important part of the products we supply, and we work continuously to enhance the efficiency of the document-handling process without compromising quality of the product. Documents provided along with the shipment include Certificate of Origin, Material Test Certificate as per EN 10204 3.1 and 10204 3.2, NACE MR10103 and NACE MR0175 certified Test Certificates.

Quality Assurance

Hastelloy Wiremesh are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Packing and Delivery

The product is wrapped and packed in wooden crates or carton boxes. Our primary goal is to deliver quality products in time, no matter where the client is located.