Inconel 601 Wire Mesh

Mumbadevi Steel India (MSI) Metals ad Tubes specializes in manufacturing and supplying high quality Inconel 601 Wiremesh. The material conforms to International standards and specifications. Inconel Wiremesh is available in a variety f shapes and sizes.

Other Names: Inconel Wire, Inconel mesh, Inconel wire mesh

Material: Inconel 601

Brand: Mumbadevi Steel India (MSI)

Manufacturer: Mumbadevi Steel India (MSI)

Inconel 601 Wire • Inconel 601 Wire Mesh Suppliers • Inconel Welded Wire Mesh • Inconel Woven Wire Mesh · UNS N06601 Wire Mesh

Inconel 601 Wire Mesh of the best quality is supplied and exported by Mumbadevi Steel India (MSI) . Our Company has built a reputation over the years for quality service and business relationships with both existing and potential customers.

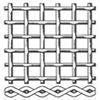

A Wire is a metal drawn out into the form of a thin flexible thread or rod. Mesh is similar to a net in that it has many attached woven or welded strands. Wire mesh is a metallic product that is used across a wide spectrum of applications all over the world. Wire Mesh is a grid formed by welding steel wires together at their intersections. Wire mesh is available in different sizes and types, and each different mesh design can be comprised of varying metals and alloys. Inconel Wire Mesh is further classified as Welded Wire Mesh and Woven Wire Mesh.

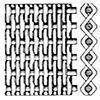

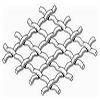

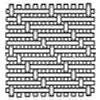

Inconel Welded Wire Mesh is a grid formed by welding steel wires together at their intersections. Welded steel wire mesh offers greater strength and versatility over woven mesh. Welded mesh will not fray or unravel, is stable and rigid, has a smooth surface and has an excellent aesthetic appearance. Available in a wide range of wire diameters and opening sizes. Inconel Woven Wire Mesh is a grid formed by weaving wires alternately over and under and are lock-crimped at their intersections. Woven wire mesh is stable and rigid, has a smooth surface and is aesthetically pleasing. Available in a wide range of wire diameters and opening sizes. Inconel Woven Wire Mesh are further classified into Plain Weave Wire Mesh, Twill Weave Wire Mesh, Dutch Weave Wire Mesh, Crimped Weave Wire Mesh, Three Heddled Weave Wire Mesh, Five Heddled Weave Wire Mesh, Plain Dutch Wire Mesh, Dutch Twill Weave, Twill Dutch Weave, Reverse Dutch Wire Mesh, Reverse Twill Dutch Wire Mesh, Cross Twill Weave.

Mumbadevi Steel India (MSI) is the market leader in the production of Inconel wiremesh of welded and woven types. Stainless steel wire mesh has varied applications in construction, food processing, automobile, mining, etc. We have the capacity to manufacture meshes with wires from 1,2 to 12 mm and of any aperture, square or rectangular. The wire mesh we supply conforms to ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360 specifications. The thickness of wire mesh is 10 mm To 100 mm Diameter in 100 mm TO 6000 mm in Length. Stainless steel wire mesh is used in a wide variety of industries since it is one of the most common materials for woven wire mesh products besides mild steel and galvanised steel with different properties. Some common applications for stainless steel wire meshes are for instance industrial sieves, chemical filters, architectural decoration, dandy roll sleeves for paper making, dryer belts and conveyor belts for the non-food industry as well as for the food industry.

Mumbadevi Steel India (MSI) have been supplying wire mesh globally since many years. We have exported our products to countries such as UAE, Qatar, USA, Europe, Thailand, South Africa, Japan, Indonesia, Russia, UK, Norway, etc. We have a good reputation amongst all our international clients.

- Wiremesh Specification: ANSI/AWCI - 01 -1992 and ASTM E 2016-11 and RRW 360

- Thickness Range: 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length

- Type: Wiremesh & Wire

- Form: Inconel 601 Plain Weave, Inconel 601 Twill Weave, Inconel 601 Dutch Weave, Inconel 601 Plain Dutch Wire Mesh, Inconel 601 Dutch Twill Weave, Inconel 601 Twill Dutch Weave, Inconel 601 Reverse Dutch Wire Mesh, Inconel 601Inconel 601 Reverse Twill Dutch Wire Mesh, Inconel 601 Cross Twill Weave

- Surface Finish: Mill Finish, PTFE Coating

- Origin: Indian Origin, European Origin, Japanese Origin

- Testing and Documents: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports

- Packing: Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests

Inconel 601 Alloy Wiremesh Sizes in Stock

| Type of Wiremesh | Thickness |

|---|---|

| Inconel Plain Weave, Inconel Twill Weave, Inconel Dutch Weave, Inconel Plain Dutch Wire Mesh, Inconel Dutch Twill Weave, Inconel Twill Dutch Weave, Inconel Reverse Dutch Wire Mesh, Inconel Reverse Twill Dutch Wire Mesh, Inconel Cross Twill Weave & Inconel Wire | 10 mm To 100 mm Diameter in 100 mm TO 6000 mm Length |

Forms of UNS N06601 in Stock

Wire

Inconel 601 Wire Available in 10 mm To 100 mm Dia

Mesh

Inconel 601 Mesh Available in 10 mm To 100 mm Dia

Welded Wire Mesh

Inconel 601 Welded Wire Mesh Available in 10 mm To 100 mm Dia

Woven Wire Mesh

Inconel 601 Woven Wire Mesh Available in 10 mm To 100 mm Dia

Plain Weave Wire Mesh

Inconel 601 Plain Weave Wire Mesh Available in 10 mm To 100 mm Dia

Twill Weave Wire Mesh

Inconel 601 Twill Weave Wire Mesh Available in 10 mm To 100 mm Dia

Dutch Weave Wire Mesh

Inconel 601 Dutch Weave Wire Mesh Available in 10 mm To 100 mm Dia

Crimped Weave Wire Mesh

Inconel 601 Crimped Weave Wire Mesh Available in 10 mm To 100 mm Dia

Three Heddled Weave Wire Mesh

Inconel 601 Three Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

Five Heddled Weave Wire Mesh

Inconel 601 Five Heddled Weave Wire Mesh Available in 10 mm To 100 mm Dia

-

Chemical Properties

-

Mechanical Properties

-

Physical Properties

-

Ni Cr Al C Mn S Si Cu Fe MIN 58.000 21.000 1.000 - - - - - Bal MAX 63.000 25.000 1.700 0.100 1.000 0.015 0.500 1.000 -

Yield Strength

0.2% Proof

(MPa)Tensile strength

(MPa)Elongation

(% in 50mm)Hardness

(HB)MIN 205 550 30.00 MAX 220 -

Density lb/in³ 0.293 Mg/m³ 8.11 Specific Heat 70°F, Btu/lb-°F 0.107 21°C, J/kg-°C 448 Melting Range °F 2480-2571 °C 1360-1411 Curie Temperature °F <-320 °C <-196 Permeability 200 oersted (15.9 kA/m) 76°F (24°C) 1.003 -109°F (-78°C) 1.004 -320°F (-196°C) 1.016

Properties of Inconel 601 alloy

Inconel 601 Cold Forming

The rate of cooling following hot-working is not critical with respect to thermal cracking. To avoid sensitization, however, the alloy should be cooled rapidly through the 1000-1400°F (540-760°C) temperature range. Inconel alloy 601 is cold-formed by conventional procedures. The alloy's work-hardening rate, is somewhat higher than the rate for Inconel alloy 600 and INCOLOY alloy 800.

Inconel 601 Hot Forming

The temperature range for hot-forming Inconel alloy 601 is 1600-2250°F (870-1230°C). Hot-working operations involving large deformations should be performed at 1900-2250°F (1040-1230°C). The alloy has low ductility at temperatures from 1200 to 1600°F (650-870°C) and should not be worked in that range. Light working at temperatures below 1200°F (650°C) can be done to develop high tensile properties.

Inconel 601 Machining

All standard machining operations are readily performed on Inconel alloy 601. For the best machinability, the alloy should be in the solution-treated condition.

Inconel 601 Welding

Inconel alloy 601 exhibits good weldability and is readily joined by conventional welding products and processes. Welding products are available which provide high joint efficiencies and heat resistance. The choice of welding product is dependent upon the service conditions to which the fabricated alloy 601 component will be exposed. Tensile properties of joints in Inconel alloy 601 are welded by the shielded-metal-arc, gas-tungsten-arc, and gas-metal-arc processes.

Inconel 601 Heat Treatment

Like other high-nickel alloys, Inconel alloy 601 must be clean before it is heated. All foreign substances such as grease, oil, paint, and shop soil must be removed from the material before a heating operation is performed. The alloy must be heated in a low-sulfur atmosphere. Fuels for open heating must be low in sulfur. To prevent excessive oxidation of the material, the furnace atmosphere should also be slightly reducing. Inconel alloy 601 is not strengthened by heat treatment. Broad ranges of strength and hardness, however, can be achieved with the alloy by the combination of cold work and annealing treatments. The amount of cold work and the section size of the material must be considered in establishing an annealing procedure.

Services We Offer

Documentation

Documentation is a very important part of the products we supply, and we work continuously to enhance the efficiency of the document-handling process without compromising quality of the product. Documents provided along with the shipment include Certificate of Origin, Material Test Certificate as per EN 10204 3.1 and 10204 3.2, NACE MR10103 and NACE MR0175 certified Test Certificates.

Quality Assurance

Inconel Wiremesh are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Material Testing

PMI Testing, Ultrasonic Test, Mechanical Testing, Spectro Tests for Chemical Analysis of the grade, Flaring Test, IGC, etc. are some of the tests conducted at our facility. We welcome stage wise inspection from any of your representative or third party inspection agencies.

Packing and Delivery

The product is wrapped and packed in wooden crates or carton boxes. Our primary goal is to deliver quality products in time, no matter where the client is located.