Inconel 718 Suppliers · UNS N07718 / WNR 2.4668

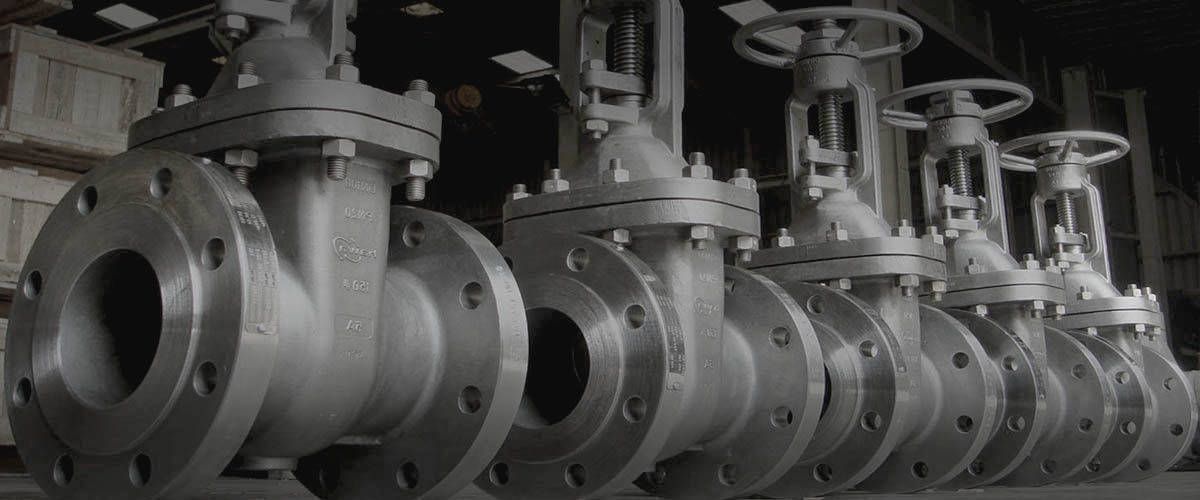

Mumbadevi Steel India (MSI) are proud supplier, distributor, stockist and exporter of Inconel 718 alloy .The unique property of Inconel 718 is due to addition of niobium in its composition which permits age hardening. It allows annealing and welding without spontaneous hardening during heating and cooling. Inconel 718 alloy can be easily moulded into complex parts due to its outstanding resistance to postweld cracking.

Other Names: Inconel 718 / Inconel ® 718 / Alloy 718 / Inconel Alloy 718 / Nickel 718 / Nickel Alloy 718 / Inconel Nickel Alloy 718 / Super Alloy 718 / Nickel Chromium 718 / Inconel Nickel Chromium 718

Material: Inconel 718 / Alloy 718 / UNS N07718 / WNR 2.4668

Brand: Mumbadevi Steel India (MSI)

Manufacturer: Mumbadevi Steel India (MSI)

Inconel 718 Suppliers | Inconel Alloy 718 Manufacturer | Inconel 718 Expoter | Inconel Alloy 718 Stockist

Inconel 718 is an Nickle based Superalloy. Inconel 718 has impressive property of high tensile and impact strength which can resist a wide range of corrosive environments at extreme temperatures. Alloy 718 consist of Carbon-Nickel-Chromium-Molybdeum-Niobium superalloy. Inconel 718 alloy possesses high resistance to Oxidation and aqueous Corrission in extreme weather/temperature along with its high strength,evan at room temperatures. Since Inconel 718 alloy can be easily fabricated within affordable cost, combined with its unique properties of good tensile, fatigue, creep and rupture strength have together resulted in its wide range of application.The niobium reacts with molybdeum to hardden the matrix of Alloy 718 and provide it with high strength without strengethining heat treatement. Inconel 718 is a Nickel-Chromium material used at temperatures ranging from-423F to 1300F. Nickel Alloy 718 has excellent weldable quality when compared to the nickel-base super alloys hardened by aluminum and titanium.

Mumbadevi Steel India (MSI) are recognized globally as exporter of UNS N07718 products for more than 15+ years now to more then 70 countries worldwide . We are certified company and CRISIL MSE 4 Rated , and our products are tested as per international standards and specifications to meet our clients custom requirements . We have huge inventory of Inconel 718 products which are manufactured as per different dimension standards and guidelines standards like ASTM, ASME, DIN, ANSI, WERKSTOFFE, EN, JIS, BS

Mumbadevi Steel India (MSI) specializes in offering hard to find items in large or small quantity. For more information on Inconel 718 products Contact Us Today !

Inconel 718 Fasteners

Inconel Alloy 718 Fastners UNS N07718|WNR 2.4668,are used to join two or more components together in a non-permanent joint , which can be dismanteled whenever needed without damaging the components . Fastners provide strength and stabilty to joints. Inconel 718 Fastners has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes. Mumbadevi Steel India (MSI) are leading suppliers , manufacturers , exporters and stockists of Inconel Alloy 718 Fasteners also known as Nickel-Chromium Alloy 718 Fasteners . We also provide various types of Inconel 718 Fastners and theire sub-types like - Inconel 718 Fastners Nuts , Inconel 718 Fastners Bolts , Inconel 718 Fastners Washers and Inconel 718 Fastners Screws.

- UNS N07718/2.4668 Inconel 718 Bolts

- UNS N07718/2.4668 Inconel 718 Nuts

- UNS N07718/2.4668 Inconel 718 Screws

- UNS N07718/2.4668 Inconel 718 Washers

- UNS N07718/2.4668 Inconel 718 Heavy Hex Nuts

- UNS N07718/2.4668 Inconel 718 Cap Nuts

- UNS N07718/2.4668 Inconel 718 Castle Nuts

- UNS N07718/2.4668 Inconel 718 Hanger Bolts

- UNS N07718/2.4668 Inconel 718 Hex Head Bolts

- UNS N07718/2.4668 Inconel 718 Hex Lag Screws

- UNS N07718/2.4668 Inconel 718 Machine Screws

- UNS N07718/2.4668 Inconel 718 Square Washer

- UNS N07718/2.4668 Inconel 718 Structural Washer

- UNS N07718/2.4668 Inconel 718 Fender Washer

- UNS N07718/2.4668 Inconel 718 Eye Screws

- UNS N07718/2.4668 Inconel 718 Hex Jam Nuts

Inconel 718 Flanges

The primary function of Inconel Alloy 718 Flanges is to strengthen a joint and to maintain their position . The gasket is pre-loaded within the Inconel Alloy 718 Flanges , and the Flanges apply the required amount of mechanical force with the help of bolts , untill the contact stress between gasket and flanges is sufficient to maintin the seal or joint .Two pipes are joined together using Alloy 718 Flanges . The joining pieces have flanges by which they are bolted together to form a smooth connection . Two pipes are connected by welding or threading and the Nickle-Chromium flanges adds protection and strength to the joint . Inconel 718 Flanges has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes.

- N07718 / Inconel 718 Reducing Weld Neck Flanges

- UNS N07718/2.4668 Inconel 718 Slip On Flanges

- UNS N07718/2.4668 Inconel 718 Blind Flanges

- UNS N07718/2.4668 Inconel 718 Socket Weld Flanges

- UNS N07718/2.4668 Inconel 718 Threaded Flanges

- UNS N07718/2.4668 Inconel 718 Lap Joint Flanges

- UNS N07718/2.4668 Inconel 718 Long Neck Flanges

- UNS N07718/2.4668 Inconel 718 Orifice Flanges

- UNS N07718/2.4668 Inconel 718 Spectacle Flanges

- UNS N07718/2.4668 Inconel 718 Raised Face Flanges

- UNS N07718/2.4668 Inconel 718 Lapped Flanges

- UNS N07718/2.4668 Inconel 718 Neck Weld Flanges

- N07718/2.4668 Inconel 718 Slip-On Reducing Flanges

- N07718 / Inconel 718 Tongue And Groove Flanges

- UNS N07718/2.4668 Inconel 718 Flat Face Flanges

- UNS N07718/2.4668 Inconel 718 Hub Blind Flanges

Inconel 718 Pipe Fittings

The role of Inconel Alloy 718 Pipe Fitting is to join two or more pipes or tubes together , provide strength to the joint with additional force to maintain increased stability , helps to change in direction or function and to ensure the smooth flow of the content inside it. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes. Mumbadevi Steel India (MSI) specialises in making Nickel-Chromium Pipe Fittings to achieve high performance even in extreme environmental conditions . We have huge stock of different types of Inconel 718 Pipe Fittings which helps in changing the direction ,changing the function , adapting to different sizes and shapes (small to big / big to small) , maintaining uniform flow and stain free . Inconel 718 Pipe Fittings are laso kbowb as Inconel 718 Buttweld Pipe Fittings.

- UNS N07718/2.4668 Inconel 718 End Cap Pipe Fitting

- N07718/2.4668 Inconel 718 Stub Ends Pipe Fittings

- UNS N07718 / Inconel 718 Pipe Nipple Pipe Fittings

- N07718/2.4668 Inconel 718 Equal Tee Pipe Fitting

- N07718/2.4668 Inconel 718 Unequal Tee Pipe Fittings

- N07718 / Inconel 718 Concentric Reducer Pipe Fitting

- N07718 / Inconel 718 Eccentric Reducer Pipe Fittings

- UNS N07718/2.4668 Inconel 718 Collar Pipe Fittings

- N07718 / Inconel 718 Long Radius Elbow Pipe Fittings

- N07718 / Inconel 718 Short Radius Elbow Pipe Fittings

- Inconel 718 Long Radius Return Bend Pipe Fittings

- N07718 / Inconel 718 Short Radius Return Bend

- N07718/2.4668 Inconel 718 Return Bend Pipe Fittings

- UNS N07718/2.4668 Inconel 718 Elbow Pipe Fittings

- N07718/2.4668 Inconel 718 Coupling Pipe Fittings

- UNS N07718/2.4668 Inconel 718 Buttweld Fittings

- UNS N07718/2.4668 Inconel Alloy 718 Pipe Fittings

Inconel 718 Sheet Plate

Inconel Alloy 718 Sheet Plates are formed through industrial process of hot and cold rolling of Inconel 718 alloy into thin , flat pieces . Multiples regular use objects can be fabricated from this sheet plates , which can be cut and bent into various sizes and shapes. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes. Mumbadevi Steel India (MSI) excels in customizing sheets plates as per clients requirements. Extremly thin sheets are known as Leaf or Foil , Sheets thicker then 6mm are considered Sheet Plates . Plates are usually thicker then Sheets.

- UNS N07718/2.4668 Inconel 718 Sheet Plate

- UNS N07718/2.4668 Inconel 718 Sheet

- UNS N07718/2.4668 Inconel 718 Shim Sheet

- UNS N07718/2.4668 Inconel 718 Rolled Sheet Coil

- UNS N07718/2.4668 Inconel 718 Rolled Sheet Strips

- UNS N07718/2.4668 Inconel 718 Inconel 718 Plate

- UNS N07718/2.4668 Inconel 718 Diamond Plate

- UNS N07718/2.4668 Inconel 718 Chequered Plate

- UNS N07718/2.4668 Inconel 718 Hot Rolled Plates

- UNS N07718/2.4668 Inconel 718 Perforated Sheet

- UNS N07718/2.4668 Inconel 718 Brushed Sheet

- UNS N07718/2.4668 Inconel 718 Polished Sheet

- UNS N07718/2.4668 Inconel 718 Thin Sheet

Inconel 718 Wire Mesh

Inconel Alloy 718 Wire Mesh is a thin yet flexible form of Inconel Alloy 718 , which is pulled out into single Cylindrical strand or thread or small rod . This thread are then wither woven or welded with each other in a pattern to form a net like structure known as mesh . Inconel Alloy 718 Wire Mesh is extremly flexible , strong and highly durable in various conditions. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes. We at Mumbadevi Steel India (MSI) , have huge inventory of different types of Inconel Alloy 718 Wire Mesh.

- UNS N07718/2.4668 Inconel 718 Wire Mesh

- UNS N07718/2.4668 Inconel 718 Plain Weave

- UNS N07718/2.4668 Inconel 718 Twill Weave

- UNS N07718/2.4668 Inconel 718 Dutch Weave

- N07718 / Inconel 718 Plain Dutch Wire Mesh

- N07718 / Inconel 718 Reverse Dutch Wire Mesh

- UNS N07718/2.4668 Inconel 718 Cross Twill Weave

- UNS N07718/2.4668 Inconel 718 Dutch Twill Weave

- UNS N07718/2.4668 Inconel 718 Twill Dutch Weave

- UNS N07718/2.4668 Inconel 718 Crimped Wire Mesh

- N07718/2.4668 Inconel 718 Reverse Dutch Weave

- N07718/2.4668 Inconel 718 Three Heddle Weave

- UNS N07718/2.4668 Inconel 718 Five Heddle Weave

Inconel 718 Forged Fittings

Inconel 718 Forged Fittings are made by Forming methods or Forging process or shaping operations , which may be performed by hammering, applying pressure , piercing , extruding or thrusting out , rolling, bending , upsetting , fusion welding , fabricating or by a combination of any of the two or more of these operations. Inconel 718 Forged Fittings are made up of pipe, tubing, plate or forgings and are generally used in mechanical and plumbing fittings. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabricated into complex parts, hence has high applicability in various processes. Mumbadevi Steel India (MSI) is a specialist of Inconel 718 Socket Weld Fittings, Inconel 718 Threaded Fittings and Inconel 718 Outlets. We have stock of various types of Inconel 718 Forgings and Inconel 718 Fittings.

- UNS N07718/2.4668 Inconel 718 Socket Weld Elbow

- UNS N07718/2.4668 Inconel 718 Socket Weld Tee

- N07718/2.4668 Inconel 718 Socket Weld Equal Cross

- N07718 / Inconel 718 Socket Weld Unequal Cross

- N07718 / Inconel 718 Socket Socket Weld Couplings

- UNS N07718/2.4668 Inconel 718 Socket Weld Cap

- UNS N07718/2.4668 Inconel 718 Socket Weld Plug

- N07718/2.4668 Inconel 718 Socket Weld Bushing

- UNS N07718/2.4668 Inconel 718 Socket Weld Union

- UNS N07718/2.4668 Inconel 718 Threaded Elbow

- UNS N07718/2.4668 Inconel 718 Threaded Tee

- N07718/2.4668 Inconel 718 Threaded Equal Cross

- N07718/2.4668 Inconel 718 Threaded Unequal Cross

- UNS N07718/2.4668 Inconel 718 Threaded Coupling

- UNS N07718/2.4668 Inconel 718 Threaded Cap

- UNS N07718/2.4668 Inconel 718 Threaded Plug

- UNS N07718/2.4668 Inconel 718 Threaded Bushing

- N07718/2.4668 Inconel 718 Threaded Hex Nipples

- N07718/2.4668 Inconel 718 Threaded Welding Boss

Inconel 718 Seamless Pipe

Mumbadevi Steel India (MSI) are proud supplier of UNS N07718 Seamless Pipes. Inconel 718 Seamless Pipe is formed by pulling a solid metal billet over a piercing rod to produce a hollow tube, which is called as seamless pipe. Inconel 718 Seamless Pipes have has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes. Nickel-Chromium content in Alloy 718 Seamless Pipe enabales them to have high resistance properties to various oxidation and corrosive environments. Its an ideal choice to carry high pressure liquid and gas.

- UNS N07718/2.4668 Inconel 718 Seamless Pipe

- UNS N07718/2.4668 Inconel 718 Pipe

- UNS N07718/2.4668 Inconel 718 Square Pipe

- UNS N07718/2.4668 Inconel 718 Round Pipe

- UNS N07718/2.4668 Inconel 718 Fabricated Pipe

- UNS N07718/2.4668 Inconel 718 Rectangular Pipe

- UNS N07718/2.4668 Inconel Alloy 718 Pipe

- UNS N07718/2.4668 Inconel Alloy 718 Seamless Pipe

- UNS N07718/2.4668 Inconel Alloy Seamless Pipe

- UNS N07718/2.4668 Alloy 718 Seamless Pipe

- UNS N07718/2.4668 Inconel Seamless Round Pipe

- UNS N07718/2.4668 Inconel Seamless Square Pipe

- UNS N07718/2.4668 Inconel Seamless Rectangular Pipe

Inconel 718 Seamless Tube

Mumbadevi Steel India (MSI) stocks a wide range of high-temperature Inconel 718 Seamless Tube, available in a variety of shapes (round, square and rectangular ),different sizes and custom specifications. Alloy 718 Seamless Tubes are majorly used in several industry for all kinds of high-temperature applications such as high-performance gas chromatography (GC), Liquid chromatography (LC), thermocouple sheathes, burners, lance tubes, gas turbine, chemical processing, furnace equipment, jet engine combustion tubes, capillary tubes heat exchangers.

- UNS N07718/2.4668 Inconel 718 Seamless Tube

- UNS N07718/2.4668 Inconel 718 Tube

- UNS N07718/2.4668 Inconel 718 Square Tube

- UNS N07718/2.4668 Inconel 718 Round Tube

- UNS N07718/2.4668 Inconel 718 Fabricated Tube

- UNS N07718/2.4668 Inconel 718 Rectangular Tube

- UNS N07718/2.4668 Inconel Alloy 718 Tube

- UNS N07718/2.4668 Inconel Alloy 718 Seamless Tube

- UNS N07718/2.4668 Inconel Alloy Seamless Tube

- UNS N07718/2.4668 Alloy 718 Seamless Tube

- UNS N07718/2.4668 Inconel Seamless Round Tube

- UNS N07718/2.4668 Inconel Seamless Square Tube

- UNS N07718/2.4668 Inconel Seamless Rectangular Tube

Inconel 718 Welded Pipe

UNS N07718 Welded Pipes is supplied and stocked by Mumbadevi Steel India (MSI) . Inconel 718 Welded Pipe has a weld seam , due to which it has lower operating pressure then Seamless Pipes . But they posses tighter dimensional tolerance as compared to seamless pipes. Inconel 718 Seamless Pipe is formed by pulling a solid metal billet over a piercing rod to produce a hollow tube, which is called as seamless pipe These pipes are hardened by Cold-Work to increase their strength manyfolds .Inconel 718 Welded Pipes has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high appalicability in various processes.

- UNS N07718/2.4668 Inconel 718 Welded Pipe

- UNS N07718/2.4668 Inconel 718 Pipe

- UNS N07718/2.4668 Inconel 718 Square Pipe

- UNS N07718/2.4668 Inconel 718 Round Pipe

- UNS N07718/2.4668 Inconel 718 Fabricated Pipe

- UNS N07718/2.4668 Inconel 718 Rectangular Pipe

- UNS N07718/2.4668 Inconel Alloy 718 Pipe

- UNS N07718/2.4668 Inconel Alloy 718 Welded Pipe

- UNS N07718/2.4668 Inconel Alloy Welded Pipe

- UNS N07718/2.4668 Alloy 718 Welded Pipe

- UNS N07718/2.4668 Inconel Welded Round Pipe

- UNS N07718/2.4668 Inconel Welded Square Pipe

- UNS N07718/2.4668 Inconel Welded Rectangular Pipe

Inconel 718 Welded Tube

At At Mumbadevi Steel India (MSI) , the manufacturing of Inconel 718 Welded Tubes is done as per strict specifications to create smoother, cleaner capillary tubing along with uniform characteristics. The close dimension control and the proprietary process creates an ultimate inner surface smoothness in the range of 10-15 RMS .Our Alloy 718 Welded Tubes possess the following characteristics- high tolerance with precise accuracy for dimensions , smooth and bright surface , and stain free from oil, grease, and other particles. Inconel 718 Welded Tubes has unique properties of good tensile, fatigue, creep and rupture strength and can be fabricated into complex parts, hence has high applicability in various processes.

- UNS N07718/2.4668 Inconel 718 Welded Tube

- UNS N07718/2.4668 Inconel 718 Tube

- UNS N07718/2.4668 Inconel 718 Square Tube

- UNS N07718/2.4668 Inconel 718 Round Tube

- UNS N07718/2.4668 Inconel 718 Fabricated Tube

- UNS N07718/2.4668 Inconel 718 Rectangular Tube

- UNS N07718/2.4668 Inconel Alloy 718 Tube

- UNS N07718/2.4668 Inconel Alloy 718 Welded Tube

- UNS N07718/2.4668 Inconel Alloy Welded Tube

- UNS N07718/2.4668 Alloy 718 Welded Tube

- UNS N07718/2.4668 Inconel Welded Round Tube

- UNS N07718/2.4668 Inconel Welded Square Tube

- UNS N07718/2.4668 Inconel Welded Rectangular Tube

Inconel 718 Tube Fittings

Inconel 718 Tube Fittings is also known as Inconel Alloy 718 Compression Fittings or Inconel Alloy 718 Ferrule Fittings or Inconel Alloy 718 Flare Fittings. It is used to create a leak-proof tight-sealing for various levels of pressures as suggested and allowed pressure of the tubing. It also join two components to each other with a stable and strong bond, holding them together in extreme condition and temperatures .The Inconel 718 Tube Fittings consists of a fitting body, a nut, a front ferrule, and a back ferrule. The two ferrules in Inconel 718 Tube fittings has separate sealing and tube gripping functions, each ferrule is optimized for its function. The front ferrule establishes a tight-seal against the fitting component and on the tubing outside diameter. As the nut is rotated, the back ferrule axially moves towards the front ferrule and radially applies an effective tube grip, thus creating a Leak-Proof Tight-Sealing. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabricated into complex parts, hence has high applicability in various processes.

- UNS N07718/2.4668 Inconel 718 Straight Union

- UNS N07718/2.4668 Inconel 718 Reducing Union

- N07718/2.4668 Inconel 718 Bulkhead Union

- N07718/2.4668 Inconel 718 Union Elbow

- N07718 / Inconel 718 Union Tee

- UNS N07718/2.4668 Inconel 718 Union Cross

- UNS N07718/2.4668 Inconel 718 Plug Tube Fittings

- UNS N07718/2.4668 Inconel 718 Cap Tube Fittings

- UNS N07718/2.4668 Inconel 718 Male Connector

- UNS N07718/2.4668 Inconel 718 Female Connector

- N07718 / Inconel 718 Male Bulkhead Connector

- UNS N07718/2.4668 Inconel 718 Elbow Tube Fittings

- N07718/2.4668 Inconel 718 Male Elbow Tube Fittings

- N07718 / Inconel 718 Female Elbow Tube Fittings

- N07718/2.4668 Inconel 718 Reducer Tube Fittings

- UNS N07718/2.4668 Inconel 718 Male Branch Tee

- UNS N07718/2.4668 Inconel 718 Female Branch Tee

- UNS N07718 / Inconel 718 Adapter Tube Fittings

- N07718/2.4668 Inconel 718 Front Ferrule

Inconel 718 Round Bar

Mumbadevi Steel India (MSI) is a specialist in supply of Inconel Alloy 718 Round Bar. It is a long cylindrical Alloy bar which is used in many commercial and industrial applications. Inconel 718 Round Bar can be used in manufacturing of pipes and tubing’s. Alloy 718 Round Bar is Available in different sizes and dimension, different forms like round bar, hex bar and square bar. Inconel 718 has unique properties of good tensile, fatigue, creep and rupture strength and can be fabrcated into complex parts, hence has high applicability in various processes. Mumbadevi Steel India (MSI) has been exporting Inconel 718 Round bars Globally and has been recognized as a specialized supplier of Inconel 718 Round Bars in many countries. We are proud exporter to countries like Europe, Australia, Japan, Indonesia

- UNS N07718/2.4668 Inconel 718 Square Bar

- UNS N07718/2.4668 Inconel 718 Hex Bar

- UNS N07718/2.4668 Inconel 718 Hexagon Bar

- UNS N07718/2.4668 Inconel 718 Flat Bar

- UNS N07718/2.4668 Inconel 718 Round Bar

- UNS N07718/2.4668 Inconel 718 Rod

- UNS N07718/2.4668 Inconel 718 Bar

- UNS N07718/2.4668 Inconel 718 Threaded Bar

- UNS N07718/2.4668 Inconel 718 Hollow Bar

- UNS N07718/2.4668 Inconel 718 Spring Bar

- UNS N07718/2.4668 Inconel 718 Cold Drawn Bar

- UNS N07718/2.4668 Inconel 718 Polish Bar

- UNS N07718/2.4668 Inconel 718 Roll Bar

- UNS N07718/2.4668 Inconel 718 Threaded Rod

- UNS N07718/2.4668 Inconel 718 Black Bar

- UNS N07718/2.4668 Inconel 718 Bright Bar

- Common Trade Names : Inconel 718 / Inconel ® 718 / Alloy 718 / Inconel Alloy 718 / Nickel 718 / Nickel Alloy 718 / Inconel Nickel Alloy 718 / Super Alloy 718 / Nickel Chromium 718 / Inconel Nickel Chromium 718.

- Specifications: UNS NO7718, WNR 2.4668, AFNOR NC19FeNb, JIS NCF 718, GOST ХН75МБТЮ, EURONORM NiCr22Mo9Nb, OR ЭИ602, BS NA 21..

- Applications of Inconel 718: Chemical Industry, Heat treating Industry, Aeronautical Industry, Nuclear Reactors, Pollution Control Equipment’s, Gas turbine engines, Cryogenic Storage Tanks.

- Features of Inconel 718: High Resistance to Aqueous Corrosion, High Resistance to High-Temperature Oxidation, High Mechanical Strength, even at room temperature, High Metallurgical Stability, Tolerant to chloride-ion stress-corrosion cracking, Ideal usability in wide range of temperature, Unique properties of good tensile, fatigue, creep and rupture strength, Age-hardenable with a unique property of slow aging, Resistant to postweld age cracking, excellent welding qualities.

- Origin: Indian Origin, European Origin, Japanese Origin.

- Testing and Documents: Mill Test Certificates, EN 10204 3.1, Chemical Reports, Mechanical Reports, Destructive Test Report, Non Destructive Test Reports, PMI Test Reports, Visual Inspection Reports, Third Party Inspection Reports, NABL Approved Lab Reports.

- Packing: Packed in Wooden Boxes, Bubble wraps, Steel Strips Bundled, or as per Customers Requests.

Available Grades in Inconel 718

Inconel 718 Specifications and Standards

| Grade | North America | France | Germany | Japan | Russia | European | Russian | British | Other Names |

|---|---|---|---|---|---|---|---|---|---|

| Inconel 718 | UNS N07718 | AFNOR NC19FeNb | WNR/DIN 2.4668 | JIS NCF 718 | GOST ХН75МБТЮ | EURONORM NiCr22Mo9Nb | OR ЭИ602 | BS NA 21 | Alloy 718/ Nickel 718 |

Properties of Inconel 718

-

Chemical Properties

C. S. Si Ti. Mn P. Nb. Al. Co. B. Mo. Ni. Fe. Cr. Cu. - - - 0.650 - - 4.750 0.200 - - 2.800 50.000 Bal 17.000 0.080 0.015 0.350 1.150 0.350 0.015 5.500 0.800 1.000 0.006 3.300 55.000 21.000 0.300 -

Mechanical Properties

Yield Str0.2% Proof(MPa) Tensile Str(MPa) Elong(% in 50mm) Hardness HBW 827 1034 20.00 298 - - - 363 -

Physical Properties

Density, lb/in3 lb/in³ Annealed 0.296 0.296 Annealed and Aged 0.297 Melting Range °F 2300-2437 °C 1260-1336 Specific Heat at 70°F 0.104 (435) 0.104 (435) Btu/lb °F (at 21°C, J/kg °C) Curie Temperature, °F (°C) Annealed Material <-320 ( <-196) Annealed and Aged Material -170 (-112) Permeability at 200 oersted and 70°F Annealed Material 1.0013 Annealed and Aged Material 1.0011

-

Inconel 718 Suppliers Manufacturer Stockist ExporterDistributor Of Inconel 718, Exporter Of Inconel 718, Importer Of Inconel 718, Inconel 718 Distributors, 2.4668 Manufacturers, Inconel 718 Exporters, Inconel 718 Importers, Inconel 718 Inventory, Alloy 718 Suppliers, Inconel 718 Manufacturers, Alloy 718 Manufacturers, Inconel 718 Price, Inconel 718 Specification, UNS N07718 Suppliers, Inconel 718 Suppliers, UNS N07718 Manufacturers, Inconel 718 Useful Info, Inconel 718 Uns N07718, Manufacturer Of Inconel 718, Stockholder Of Inconel 718, 2.4668 Suppliers, Stockist Of Inconel 718, Supplier Of Inconel 718, Trader Of Inconel 718, Traders Of Inconel 718, Types Of Inconel 718, Wholesaler Of Inconel 718, Inconel 718 Suppliers Australia, Inconel 718 Suppliers Brazil, Inconel 718 Suppliers Canada, Inconel 718 Suppliers Chile, Inconel 718 Suppliers Czechia, Inconel 718 Suppliers Egypt, Inconel 718 Suppliers France, Inconel 718 Suppliers Germany, Inconel 718 Suppliers Greece, Inconel 718 Suppliers India, Inconel 718 Suppliers Indonesia, Inconel 718 Suppliers Iran, Inconel 718 Suppliers Iraq, Inconel 718 Suppliers Ireland, Inconel 718 Suppliers Israel, Inconel 718 Suppliers Italy, Inconel 718 Suppliers Japan, Inconel 718 Suppliers Kuwait, Inconel 718 Suppliers Malaysia, Inconel 718 Suppliers Netherland, Inconel 718 Suppliers Oman, Inconel 718 Suppliers Qatar, Inconel 718 Suppliers Russia, Inconel 718 Suppliers Saudi Arabia, Inconel 718 Suppliers Singapore, Inconel 718 Suppliers South Africa, Inconel 718 Suppliers South Korea, Inconel 718 Suppliers Spain, Inconel 718 Suppliers Thailand, Inconel 718 Suppliers United Arab Emirates (UAE), Inconel 718 Suppliers United Kingdom (UK), Inconel 718 Suppliers United States (US), Inconel 718 Suppliers Romania, Inconel 718 Suppliers Finland, Inconel 718 Suppliers Argentina, Inconel 718 Suppliers Venezuela, Inconel 718 Suppliers Kazakhstan, Inconel 718 Suppliers Europe.