Seamless and Welded Pipe Manufacturing

Seamless Pipe Manufacturing Process

Seamless pipe is Strongest amongst all pipes type as it has a Homogeneous structure throughout pipe length.

- Seamless pipes are manufactured in a verity of size and schedule. However, there is a Restriction on the manufacturing of large diameter pipe. Seamless pipes are widely used in the manufacturing of pipe fittings such as bends, elbows, and tees.

- Various Manufacturing process are explained in detail;

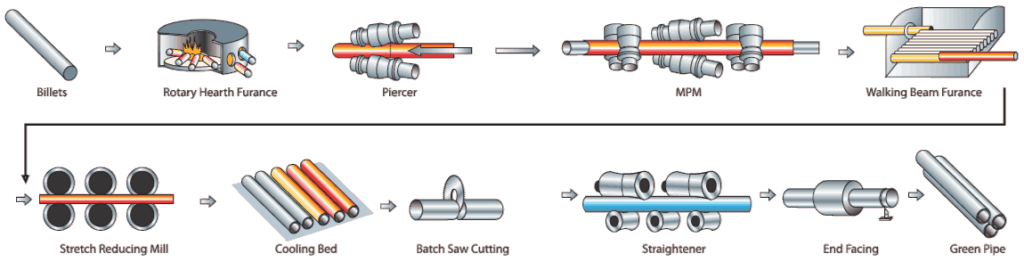

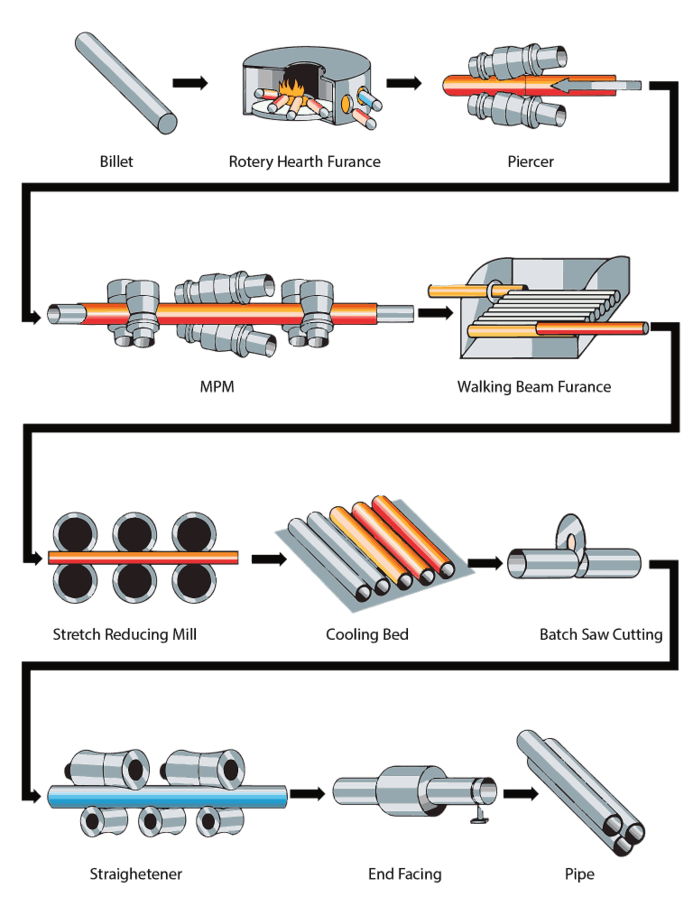

Mandrel Mill Process

In the Mandrel Mill pipe manufacturing process, the steel billet is heated to high temperature in the rotary furnace. A cylindrical hollow, which is also known as mother hollow, is produced with the help of a rotary piercer and set of roller arrangement that keeps the piercer at the center of the billet.

The outside diameter of the piercer is approximately that of the inside diameter of the finished pipe. With the help, secondary roller arrangement outside diameter and thickness are achieved.

Mannesmann Plug Mill Pipe Manufacturing Process

Mannesmann was a German engineer who has invented this pipe manufacturing process. The only difference between the Plug mill process and the Mandrel mill process is that in the mandrel method inside diameter is achieved in a single pass whereas in Mannesmann multi-stage reduction is possible.

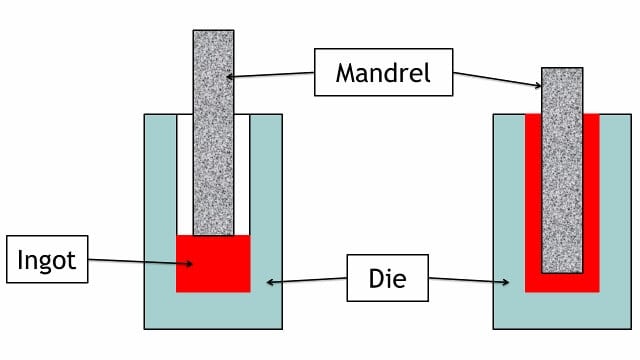

Forged Seamless Pipe Manufacturing Process

In a Forging pipe manufacturing process, a heated billet is placed in forging die that has a diameter slightly larger than the finished pipe. A hydraulic press of forging hammer with matching inside diameter is used to create cylindrical forging.

Once this forging is done pipe is machined to achieve the final dimension. Forging pipe manufacturing process is used to manufactured large diameter seamless pipes that cannot be manufactured using traditional methods. Forged pipes are normally used for the steam header.

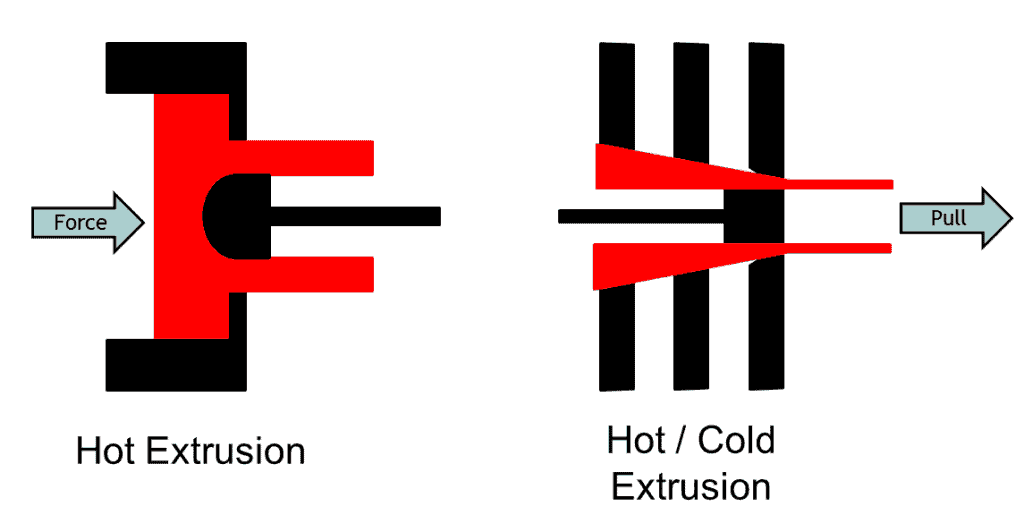

Extrusion Processes

In an extrusion pipe manufacturing, a heated billet is placed inside the die. A hydraulic ram pushes the billet against the piercing mandrel, material flows from the cylindrical cavity between die and mandrel. This action produces the pipe from the billet.

Sometimes pipe manufactured produce pipe with a high thickness which is known as mother hollow. Many secondary pipes manufactured used this mother hollow to produce pipes with different dimensions.

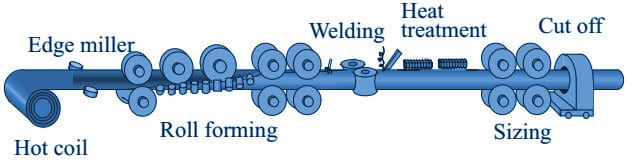

Welded Pipe Manufacturing Process

Welded Pipes are manufactured from Plate or continues Coil or strips. To manufacture a welded pipe, the first plate or coil is rolled in the circular section with the help of a plate bending machine or by a roller in the case of a continues process.

Once the circular section is rolled from the plate, the pipe can be welded with or without filler material. A welded pipe can be manufactured in large sizes without any upper restriction. Welded pipe with filler material can be used in the manufacturing of long radius bends and elbow.

Welded pipes are cheaper with compared to the seamless pipe and also Weak due to the weld

There are different welding methods used to weld the pipe.

- ERW- Electric Resistance Welding

- EFW- Electric Fusion Welding

- HFW- High-frequency welding

- SAW- Submerged Arc Welding (Long seam & Spiral Seam)

ERW Steel Pipe Manufacturing Process

In the ERW / EFW / HFW pipe process, the first plate is formed in a cylindrical shape and the longitudinal edges of the cylinder formed are welded by flash-welding, low-frequency resistance-welding, high-frequency induction welding, or high-frequency resistance welding.

SAW Pipe Manufacturing Process

In the SAW welding process, external filler metal (wire electrodes) are used to join the formed plates. SAW pipes can have a single longitudinal seam of double longitudinal seam depend on the size of the pipe.

SAW pipes are also available in the spiral seam, which is continually rolled from the single plate coil. The production rate of the spiral SAW pipe is very high as compared to the Straight SAW pipe. However, Spiral SAW pipes are only used in low-pressure services such as water, non-critical process services, etc.