Spectacle Blind, Slip Blind and Spacers (Paddle Blank and Spacer)

Spectacle blind, spades, and spacers are also known as figure-8, paddle blank, Slip blind, and spacer. These are three different components that used in piping for positive isolation of the section of a line or equipment during maintenance and shutdown.

They are also used during operation wherever positive shutoff is required to prevent leakage of one fluid into another. Let’s see each of them.

What is Spectacle Blind or figure 8 blind?

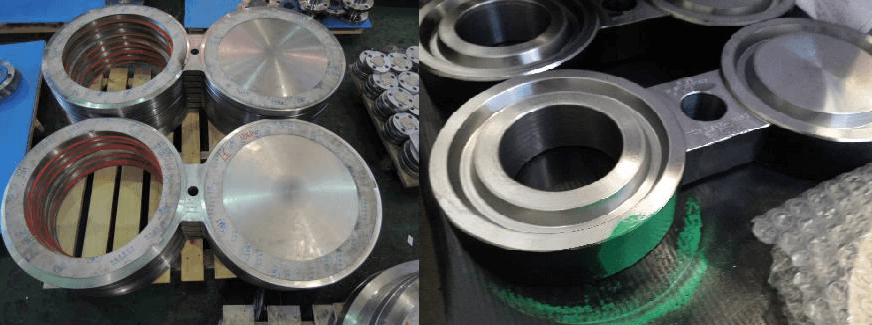

This blind is a pressure-retaining plate with one solid end and one open end connected with a small nose piece (small tie bar). Now, look at the image of this blind.

As it resembles a pair of eyeglasses or numeric number Eight, Spectacle blind is also known as a figure 8 blind and sometimes refer collectively as figure 8 spectacle blind.

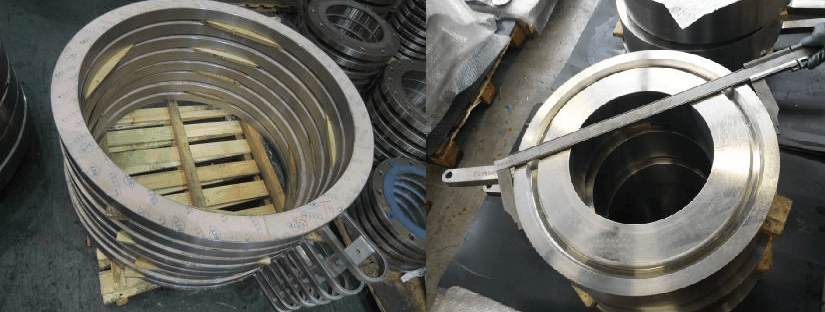

The inside diameter of the open end is equal to the pipe ID to facilitate flow from the line. The use of spectacle blanks ensures that the companion spacer or blind is on hand when needed.

However, above NPS 12 the weight is high, and it is difficult to handle. To avoid excessive load on the line, separate spacers and blanks are used which known as paddle blank and spade.

Paddle blank or Spade or Slip Blind

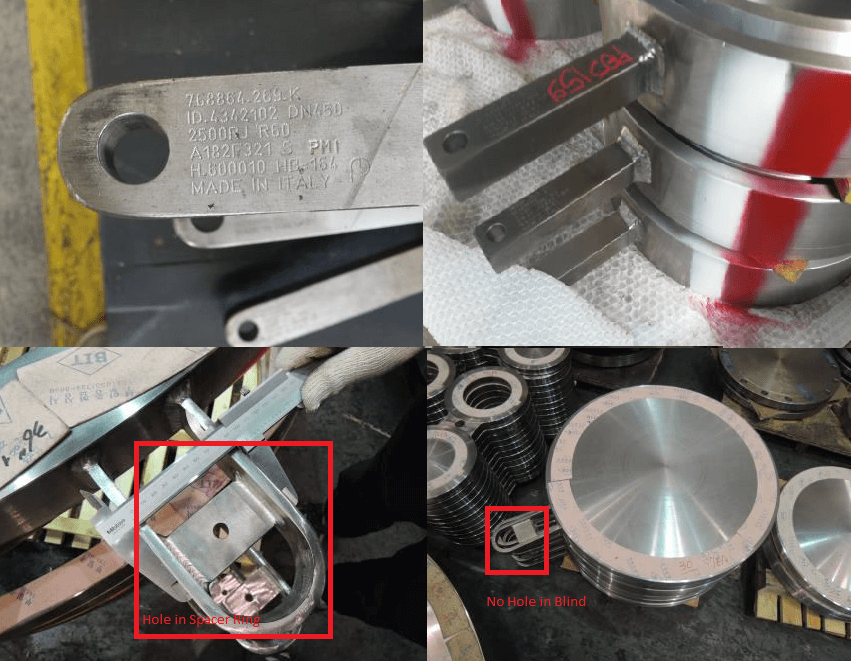

Paddle blank or spade is similar to the solid end of the spectacle blind. A handle is welded with the spec blind. See the image.

Paddle Spacer or Spacer Ring

Paddle blank or spacer ring is similar to the open end of the spectacle blind. A handle is welded with the blank. See the image.

It is very important to know whether spacer or blind is installed in the line by just looking at their handle. To avoid confusion handle of the blank has a solid bar welded to it whereas the handle of the paddle spacer has a drilled hole at the end of the handle or formed eye. See the image for clarification

Use of Spades and Spacers Blinds

Spectacle Blind, Spades, and Spacers are used to provide flexibility during maintenance and operation. Therefore, it is essential to consider this during the design of a Piping system. Blanks are installed in a horizontal line. In general, you can see the use of these flanges at the following location;

- Inlets and outlets of static equipment

- At inlets and outlets of rotary equipment

- Inlets and outlets of the fired heater and common headers

- In bypass line

- Unit battery limit

Spec blind is installed between the ASME B16.5 Flanges and they are designed as per ASME B16.48 (Line Blanks). Sometimes people use term spec blind flanges or brake flange, but you should know that they are two different items.

Class & Types of the Spectacle Blind

ASME B16.48 standard that covers Line Blanks. This standard covers the Spectacle Blind, Spades, and Spacers with pressure class 150, 300, 600, 900, 1500, and 2500 as listed in ASME B16.5.

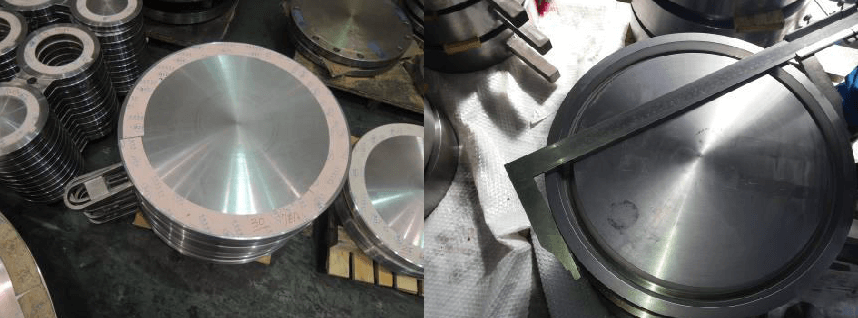

Spec blinds are available in the following face type;

- Raised Face

- Female Ring-Joint Blanks

- Male Ring-Joint Blanks

Refer to the image above for raised face and female ring joint blanks.